What Is the Standard, ISO 9001?

As you delve into the world of quality management systems, it’s essential to understand the progressive enhancements that have shaped ISO 9001 into the robust standard it is today. Our platform, ISMS.online, recognises the importance of this evolution and how it can influence your organisation’s approach to quality management.

Iterative Improvements to ISO 9001:2015

ISO 9001 has undergone several revisions, each incorporating feedback and adapting to the changing business landscape. The journey from the original ISO 9001:1987, which was based on the British Standard BS 5750, to the current ISO 9001:2015 reflects a shift towards a more process-oriented and risk-aware framework. This evolution ensures that the standard remains relevant and continues to set a benchmark for quality.

Structural and Focus Changes in ISO 9001:2000

The ISO 9001:2000 revision marked a significant change by introducing a process-oriented structure. This shift emphasised the importance of managing processes and the interactions between them, laying the groundwork for a systematic approach to quality management that you can apply within your organisation.

Risk-Based Thinking in ISO 9001:2015

With the advent of ISO 9001:2015, risk-based thinking became a cornerstone of the standard. This approach encourages organisations like yours to proactively identify and mitigate risks, ensuring a resilient and adaptable quality management system.

Integration of the PDCA Cycle

The Plan-Do-Check-Act (PDCA) cycle is integral to ISO 9001's framework, providing a methodical approach to continuous improvement. By adopting this cycle, your organisation can foster a culture of ongoing enhancement, crucial for maintaining a competitive edge in today's market.

Book a demoDistinguishing ISO 9000 From ISO 9001

Understanding the nuances between ISO 9000 and ISO 9001 is pivotal for your organisation as you consider the adoption of a Quality Management System (QMS). At ISMS.online, we aim to clarify these distinctions to ensure you make an informed decision that aligns with your strategic objectives.

Scope and Application Differences

ISO 9000 serves as the foundation, providing the fundamentals and vocabulary for quality management systems. In contrast, ISO 9001 is the standard that specifies the requirements for establishing, implementing, maintaining, and continually improving a QMS. Essentially, ISO 9000 lays the groundwork, while ISO 9001 outlines the actionable criteria necessary for certification.

ISO 9001 as the Definitive Standard

ISO 9001 is often considered the definitive standard within the ISO 9000 family because it concretises the concepts introduced in ISO 9000 into specific requirements. This standard is what organisations like yours will be audited against when seeking certification.

Detailed Framework for Quality Management

ISO 9001 provides a detailed framework for quality management by incorporating the principles of the ISO 9000 series into a set of actionable requirements. These include customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision-making, and relationship management.

Implications of Choosing ISO 9001

Choosing ISO 9001 over ISO 9000 means committing to a systematic approach to quality that is measurable and auditable. It implies a readiness to enhance customer satisfaction and drive continuous improvement within your organisation’s processes and outcomes.

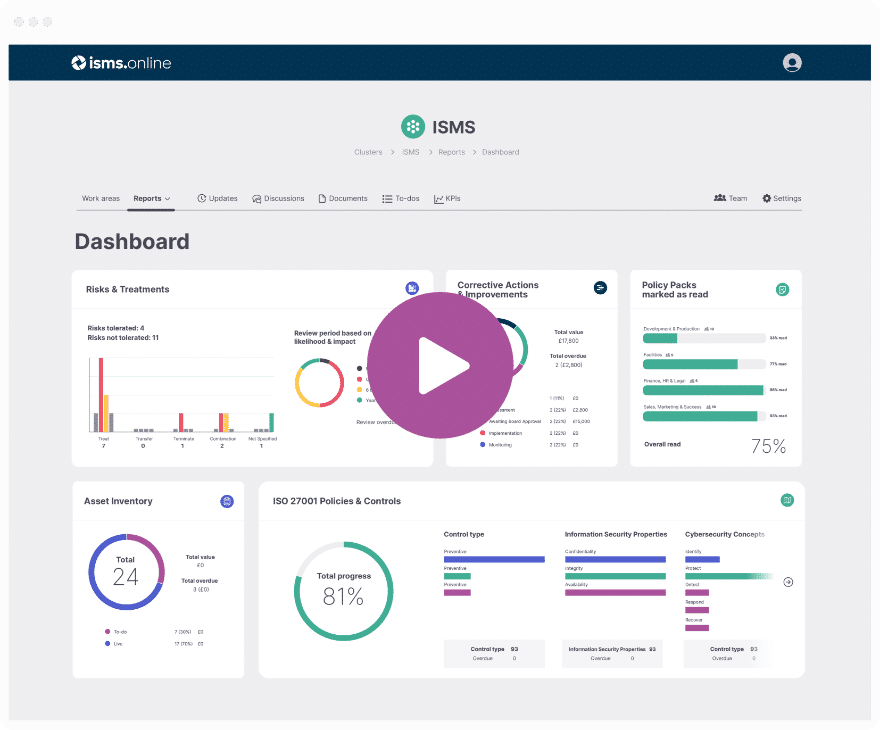

Get an 81% headstart

We've done the hard work for you, giving you an 81% Headstart from the moment you log on.

All you have to do is fill in the blanks.

The Core Components of ISO 9001’s Quality Management Principles

When you’re exploring the adoption of ISO 9001 for your organisation, it’s crucial to grasp the foundational principles that underpin the standard. At ISMS.online, we emphasise these principles as they form the bedrock of an effective Quality Management System (QMS).

Seven Foundational Principles of ISO 9001

ISO 9001 is built on seven key principles that guide the quality management approach:

- Customer Focus: prioritising customer needs to enhance satisfaction.

- Leadership: Establishing unity of purpose and direction.

- Engagement of People: Involving and empowering employees at all levels.

- Process Approach: Managing activities as processes to achieve more efficient results.

- Improvement: Pursuing continual improvement as an organisational objective.

- Evidence-Based Decision Making: Making informed decisions based on data analysis.

- Relationship Management: Cultivating relationships with stakeholders to optimise performance.

Customer Focus in Quality Management

Customer focus is the driving force behind ISO 9001, ensuring that your QMS consistently meets customer requirements and strives to exceed customer expectations. This principle is about understanding and responding to current and future customer needs, a critical aspect of sustaining business success.

Encouraging a Process Approach

ISO 9001 encourages a process approach to quality management by prompting you to consider activities in terms of processes within a system. This approach helps in understanding and managing interrelated processes as a system, contributing to the organisation’s effectiveness and efficiency.

Significance of Relationship Management

Relationship management within ISO 9001 is about managing the organisation’s relationships with interested parties, such as suppliers and partners, to achieve sustained success. It recognises that relationships with external providers and partners can influence the performance of your QMS.

Implementing ISO 9001: A Step-by-Step Process

Embarking on the journey to ISO 9001 certification can be a transformative process for your organisation. At ISMS.online, we understand the intricacies involved and are committed to guiding you through each step.

Initial Steps for ISO 9001 Implementation

The first steps towards ISO 9001 implementation are critical and involve:

- Understanding the Standard: familiarise yourself with the requirements of ISO 9001.

- Gap Analysis: Assess your current processes against ISO 9001 requirements to identify areas for improvement.

- Management Commitment: Secure the commitment from top management, as their leadership is essential for driving the QMS.

Documenting Processes in Compliance with ISO 9001

Documenting your processes is a cornerstone of ISO 9001 compliance. This includes:

- Quality Policy: Articulate your commitment to quality and customer satisfaction.

- Quality Objectives: Set measurable goals aligned with the quality policy.

- Process Documentation: Create documents that describe your processes, their interactions, and responsibilities.

Management’s Role in Successful ISO 9001 Implementation

Management plays a pivotal role by:

- Providing Resources: Allocating the necessary resources for the QMS.

- Leading by Example: Demonstrating a commitment to the QMS through actions.

- Promoting a Quality Culture: Encouraging a company-wide culture of continuous improvement.

ISMS.online’s Facilitation of the ISO 9001 Implementation Process

Our platform, ISMS.online, simplifies the implementation process by providing:

- Pre-configured QMS: Jumpstart your implementation with our tailored system.

- Expert Templates and Guidance: utilise our resources to ensure compliance and efficiency.

- Virtual Coach: Navigate ISO 9001 requirements with our expert support.

Manage all your compliance in one place

ISMS.online supports over 100 standards

and regulations, giving you a single

platform for all your compliance needs.

The ISO 9001 Certification Journey

Embarking on the path to ISO 9001 certification is a strategic decision that can significantly enhance your organisation’s quality management practices. At ISMS.online, we’re committed to supporting you through this transformative journey.

Meeting ISO 9001 Certification Criteria

To achieve ISO 9001 certification, your organisation must:

- Develop a QMS: This system should meet the requirements specified in the ISO 9001 standard.

- Document Processes: Clearly document all processes that contribute to quality management.

- Implement Changes: Apply the documented processes and ensure they are fully operational within your organisation.

- Conduct Internal Audits: Regularly review your system to ensure compliance and identify areas for improvement.

Assessing Adherence to ISO 9001 Standards

The certification process involves a rigorous assessment by an external auditor, who will:

- Review Documentation: Examine your QMS documentation for completeness and accuracy.

- Evaluate Implementation: Assess the effectiveness of your QMS in practice.

- Identify Non-Conformities: Highlight areas that do not meet ISO 9001 standards and require corrective action.

Understanding Costs and Timeframes

Typical costs and timeframes for obtaining ISO 9001 certification can vary, but generally include:

- Consultation Fees: Costs associated with hiring experts or consultants to prepare for certification.

- Certification Fees: Charges from the certifying body to conduct the audit and issue the certificate.

- Time Investment: The process can take anywhere from 3 to 6 months, depending on the size and complexity of your organisation.

Maintaining ISO 9001 Certification

To maintain certification, you must:

- Conduct Annual Audits: Perform regular internal audits and address any identified issues.

- Undergo Recertification: Every three years, complete a recertification audit to ensure ongoing compliance with ISO 9001 standards.

By adhering to these guidelines and leveraging the tools and expertise available through ISMS.online, you can navigate the certification process with confidence and achieve accreditation that underscores your commitment to quality.

The Role of Audits in ISO 9001 Compliance

Audits are a fundamental component of the ISO 9001 framework, serving as a mirror to reflect the effectiveness of your Quality Management System (QMS). At ISMS.online, we understand the critical nature of these audits and provide the tools and guidance to ensure they are conducted efficiently and effectively.

Importance of Internal and External Audits

Internal audits are essential for self-assessment, allowing you to identify areas of improvement within your QMS. External audits, conducted by independent certifying bodies, are crucial for validating compliance with ISO 9001 standards and for the certification process itself. Together, they ensure that your QMS is not only compliant but also aligned with best practices for quality management.

Utilising an Audit Checklist

An audit checklist is an invaluable tool that provides a comprehensive list of criteria your QMS must meet. It guides auditors through the evaluation process, ensuring no element of the standard is overlooked. By using our platform’s integrated checklists, you can streamline this process and maintain a clear focus on compliance.

Compliance Officer’s Audit Responsibilities

As a Compliance Officer, your responsibilities during the audit process include:

- Ensuring all necessary documentation is prepared and accessible.

- Facilitating the auditor’s understanding of your QMS.

- Addressing any findings and implementing corrective actions.

Audits Fostering Continuous Improvement

Audits are not just about compliance; they are a catalyst for continuous improvement. By identifying gaps and areas for enhancement, audits drive your organisation towards higher quality standards and operational excellence. With ISMS.online, you can leverage audit findings to build a stronger, more resilient QMS.

Compliance doesn't have to be complicated.

We've done the hard work for you, giving you an 81% Headstart from the moment you log on.

All you have to do is fill in the blanks.

ISO 9001’s Impact and Competitive Advantage

Achieving ISO 9001 certification is a clear indicator of an organisation’s dedication to quality management and operational excellence. At ISMS.online, we help you leverage this standard to elevate your business practices and gain a competitive edge.

Contribution to Organisational Excellence

ISO 9001 certification is more than a badge of honour; it’s a testament to your organisation’s commitment to quality. By adhering to ISO 9001 standards, you demonstrate a systematic approach to managing and improving your business processes. This commitment to excellence can lead to:

- Enhanced operational performance

- Greater accountability and consistency

- Improved customer satisfaction

Gaining a Competitive Edge with ISO 9001

In today’s market, differentiation is key. ISO 9001 certification can provide that distinction by:

- signalling to customers and stakeholders that you prioritise quality

- Opening doors to new markets where ISO 9001 is a requirement

- Providing a framework for continuous improvement that keeps you ahead of competitors

Financial and Performance-Related Benefits

organisations certified to ISO 9001 often experience financial and performance-related benefits, including:

- Streamlined operations and reduced costs

- Increased efficiency and productivity

- Better resource management

Enhancing Efficiency and Reducing Waste

ISO 9001 encourages a process approach that focuses on efficiency and waste reduction. By optimising your processes, you can:

- minimise errors and rework

- Reduce costs associated with waste

- Improve overall efficiency

Through our platform, we provide the tools and guidance necessary to achieve these benefits and ensure your ISO 9001 journey is a success.