Operational Planning and Control, Clause 8.1

When you’re aiming to align your organisation’s operational processes with ISO 9001:2015 standards, understanding Clause 8.1 is pivotal. This clause serves as the backbone for operational planning and control, ensuring that your products and services consistently meet customer requirements and quality benchmarks.

Planning and Implementing Processes

Under Clause 8.1, you must meticulously plan and implement processes that are crucial for the operational lifecycle of your products and services. This includes defining criteria for processes and their outputs, and implementing control measures to ensure that these criteria are met.

Integrating Compliance with Product and Service Delivery

Our platform, ISMS.online, recognises the importance of integrating legal and statutory compliance into product and service delivery. We provide tools that help you ensure your operations are not only efficient but also compliant with all relevant regulations.

The Role of Operational Planning in ISO Certification

Operational planning is not just about meeting current standards; it’s about setting a foundation for continual improvement, which is essential for achieving and maintaining ISO 9001:2015 certification.

ISMS.online: Your Partner in Compliance

At ISMS.online, we facilitate your journey towards compliance with Clause 8.1. Our platform offers a structured approach to manage your operational planning and control, aligning with the rigorous requirements of ISO 9001:2015.

Book a demoRequirements for Products and Services, Clause 8.2

In the realm of ISO 9001:2015, Clause 8.2 is a cornerstone for ensuring that customer requirements are not just met but exceeded. It emphasises the importance of effective communication and feedback mechanisms, which are critical for maintaining a customer-centric approach to quality management.

Managing Customer Communication and Feedback

Effective management of customer communication and feedback is essential for ISO compliance. At ISMS.online, we advocate for establishing clear channels for customer interactions, ensuring that feedback is not only received but also acted upon. This allows for continuous improvement and helps in aligning your services with customer expectations.

Best Practices for Property Control and Contingency Planning

Property Control: Safeguarding customer and organisational property is paramount. We recommend implementing stringent control measures, including clear identification, tracking, and protection protocols.

Contingency Planning: Anticipating and planning for potential disruptions ensures operational resilience. Our platform provides the tools you need for effective contingency planning, helping you to maintain service quality even in unforeseen circumstances.

Ensuring Product and Service Requirements

Clause 8.2 mandates that product and service requirements are clearly defined, communicated, and understood. By leveraging our platform, you can ensure that these requirements are integrated into every stage of your operation, from initial customer interaction to final delivery.

Enhancing Customer Satisfaction Metrics

To enhance customer satisfaction, we encourage the adoption of strategies that focus on understanding and meeting the unique needs of your customers. Regularly reviewing customer feedback and satisfaction metrics can lead to improvements in service quality and customer loyalty.

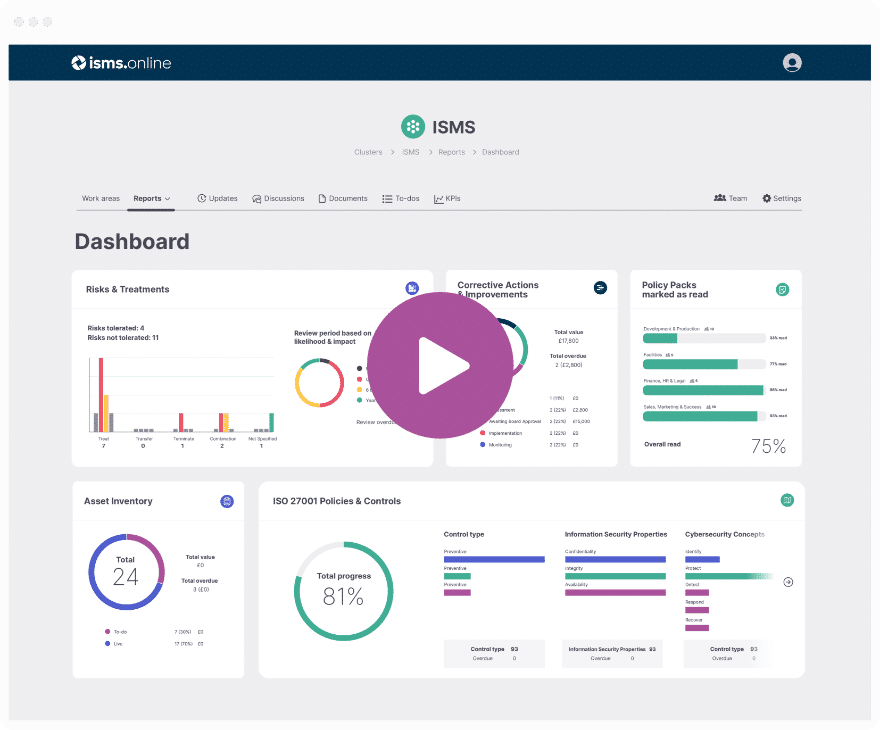

Get an 81% headstart

We've done the hard work for you, giving you an 81% Headstart from the moment you log on.

All you have to do is fill in the blanks.

Design and Development, Clause 8.3

Clause 8.3 of ISO 9001:2015 is a critical component that outlines the necessary stages and controls for the design and development of products and services. It ensures that these processes are systematically executed to meet customer and regulatory requirements.

Stages and Controls in Design and Development

The design and development process is structured into distinct stages, each requiring specific controls to ensure quality and efficiency. These stages typically include:

- Planning: Determining the objectives and requirements for the design and development of products and services.

- Inputs: Gathering and defining the inputs necessary for the design and development process.

- Controls: Applying controls to the design and development process to ensure the outputs meet the input requirements.

- Outputs: The results of the design and development process, which must be clearly documented and validated.

- Review: Regular reviews of the design and development process to ensure it continues to meet the requirements.

- Verification and Validation: Ensuring that the final product or service meets the initial design requirements and is fit for the intended purpose.

Competitive Advantage through Clause 8.3

Incorporating Clause 8.3 into your operations can yield a significant competitive advantage. By adhering to these standards, you ensure that your products and services are not only of high quality but also innovative and responsive to market needs.

The Role of Market Research and Customer Feedback

Market research and customer feedback are integral to the design and development process. They provide valuable insights that can lead to improvements and innovations, ensuring that the end product aligns with customer expectations and market trends.

ISMS.online’s Support for Design and Development

At ISMS.online, we understand the importance of robust design and development controls. Our platform offers comprehensive tools and resources to support you in implementing Clause 8.3 effectively, ensuring that your design and development processes are well-managed and compliant with ISO 9001:2015 standards.

Quality in External Partnerships, Clause 8.4

Clause 8.4 of ISO 9001:2015 is dedicated to the management of externally provided processes, products, and services. It is essential for ensuring that any external inputs to your quality management system (QMS) meet your specified requirements and do not negatively impact the quality of your output.

Evaluation and Audit Processes

To maintain the integrity of your QMS, it is crucial to evaluate and audit your external providers. At ISMS.online, we recommend:

- Conducting thorough evaluations of potential suppliers to ensure they can meet your requirements.

- Performing regular audits to verify ongoing compliance and the quality of provided products and services.

Pre-Qualification of External Providers

Pre-qualification acts as a proactive measure to ensure quality management. By vetting providers before engagement, you can:

- Establish a baseline for quality expectations.

- Streamline your supplier selection process, saving time and resources.

Key Considerations for Controlling Externally Provided Processes

When controlling externally provided processes, consider:

- The potential impact on your final product or service quality.

- The necessity for clear communication of your quality requirements.

- The alignment of external processes with your QMS objectives.

Uniformity and Compatibility in Quality Management

Clause 8.4 is integral to achieving uniformity and compatibility in quality management across your supply chain. By adhering to this clause, you ensure that all components of your QMS work cohesively, regardless of the origin of products or services.

Manage all your compliance in one place

ISMS.online supports over 100 standards

and regulations, giving you a single

platform for all your compliance needs.

Production and Service Provision, Clause 8.5

Clause 8.5 of ISO 9001:2015 is a critical element that focuses on the controls necessary for the effective production and service provision. This clause ensures that your operations are conducted under controlled conditions, leading to consistent quality and customer satisfaction.

Essential Controls for Production and Service Provision

To achieve mastery in production and service provision, the following controls are essential:

- Defining and documenting process criteria to ensure operations meet quality standards.

- Monitoring and reviewing the effectiveness of these processes regularly.

- Maintaining a state of readiness for production and service delivery through proper resource allocation.

Traceability and Property Safeguarding with ISMS.online

At ISMS.online, we understand the importance of traceability and safeguarding customer and organisational property. Our platform helps you:

- Maintain records that provide traceability of products and services.

- Protect property provided by customers or external providers from loss, damage, or misuse.

Documented Information Requirements

For Clause 8.5 compliance, documented information must include:

- Specifications for products, services, and processes.

- Records of conformity with acceptance criteria.

- Traceability records where applicable.

Ensuring Quality and Compatibility

Clause 8.5 is instrumental in maintaining the quality and compatibility of your service provision by:

- standardising production and service processes to meet customer and regulatory requirements.

- Ensuring that changes to processes are controlled to prevent unintended consequences.

Release of Products and Services, Clause 8.6

Clause 8.6 of ISO 9001:2015 is integral to the quality assurance process, focusing on the acceptance criteria for products and services. It ensures that what you deliver meets both customer expectations and regulatory requirements.

Documented Acceptance Criteria for Quality Checks

To ensure quality, you must establish and document acceptance criteria for your products and services. These criteria serve as benchmarks for:

- Testing: Verifying that products and services meet defined specifications.

- Inspection: Conducting thorough reviews to ensure compliance with quality standards.

- Validation: Confirming that products and services fulfil their intended use.

Conducting Testing, Verification, and Validation

At ISMS.online, we support your efforts to conduct effective testing, verification, and validation by providing:

- Structured methodologies to ensure systematic quality checks.

- Tools for documenting and tracking the results of these checks.

The Role of Clause 8.6 in Operational Excellence

Clause 8.6 is pivotal in achieving operational excellence. It ensures that all products and services undergo rigorous quality checks before reaching the customer, thereby upholding the integrity of your QMS.

Implementing Effective Acceptance Checks

To implement effective acceptance checks, we recommend:

- Integrating these checks into your operational processes to maintain a consistent quality standard.

- Utilising ISMS.online’s resources to streamline the acceptance process, ensuring that all products and services are evaluated against the documented criteria before release.

Compliance doesn't have to be complicated.

We've done the hard work for you, giving you an 81% Headstart from the moment you log on.

All you have to do is fill in the blanks.

Nonconformity and Corrective Actions, Clause 8.7

Managing nonconformity effectively is a critical aspect of maintaining a robust Quality Management System (QMS). Clause 8.7 of ISO 9001:2015 provides a structured approach to control nonconforming outputs, ensuring that any issues are addressed promptly and efficiently.

Procedures for Nonconforming Product/Service Control

When you encounter a nonconforming product or service, the following procedures should be implemented:

- Identification: Quickly and accurately identify nonconformity within your operations.

- Control: Take appropriate actions to contain and control the nonconforming output to prevent its unintended use or delivery.

- Correction: Apply necessary corrections to address the nonconformity and prevent recurrence.

Contribution to Continual Improvement

Correction and segregation are not merely about fixing problems; they are opportunities for continual improvement. By analysing nonconformities, you can identify underlying issues and implement systemic changes to enhance your QMS.

Documented Evidence in Nonconformity Management

Documented evidence is vital in nonconformity management. It provides:

- Traceability: Keeping records of nonconformities and the actions taken.

- Accountability: Ensuring that all corrective actions are verifiable and effective.

ISMS.online: Streamlining Nonconformity Management

At ISMS.online, we offer tools and resources to help you manage nonconforming outputs effectively. Our platform enables you to:

- Document nonconformities and corrective actions taken.

- Track the effectiveness of these actions over time.

- Ensure compliance with ISO 9001:2015 through structured nonconformity management processes.

Further Reading

Integrated Management Systems and Annex L Alignment

Annex SL, also known as Annex L, is a framework that provides a consistent structure for all ISO management system standards. This alignment is crucial for organisations like yours that may be implementing multiple management systems.

Achieving Management System Consistency

Annex SL facilitates a uniform structure, making it easier for you to integrate various management systems. It standardises core definitions and terms, which is essential for maintaining consistency across your QMS and other management systems.

Benefits of an Integrated Framework

An integrated framework simplifies the complexity of managing multiple standards. It leads to:

- Efficiency: Streamlining processes and reducing duplication.

- Clarity: Providing a clear understanding of how different systems interact.

- Cohesion: Ensuring that all parts of the organisation are working towards the same objectives.

ISMS.online’s Support for Operational Planning

At ISMS.online, we provide tools and guidance to help you align with Annex L. Our platform is designed to:

- Simplify the integration of various management systems.

- Provide a clear roadmap for operational planning and control.

- Ensure that your systems are compliant with the high-level structure of Annex SL.

The Importance of Consistency

Consistency in your management systems is not just about compliance; it’s about building trust with interested parties. It demonstrates your commitment to quality management and continuous improvement, which are key to stakeholder confidence.

Internal Audits and Continual Improvement Mechanisms

Internal audits are a vital component of the ISO 9001:2015 framework, serving as a mirror to reflect the current state of your Quality Management System (QMS). They are the systematic examinations that provide the feedback necessary for continual improvement.

Systematic Examination Methods in Internal Audits

During internal audits, we employ systematic examination methods that include:

- Document Review: Evaluating the adequacy of documented information against ISO 9001 requirements.

- Process Evaluation: Assessing the effectiveness of processes in achieving desired outcomes.

- Interviews: Gathering insights from personnel to verify that practices align with documented procedures.

Contribution to QMS Effectiveness

Internal audits contribute to the effectiveness of your QMS by:

- Identifying areas of non-conformance and potential improvement.

- Ensuring that processes are consistently applied across the organisation.

- Verifying that the QMS is effectively implemented and maintained.

Performance Enhancement and Process Refinement

Key elements for performance enhancement and process refinement include:

- Benchmarking: Comparing current performance against best practices or standards.

- Root Cause Analysis: Identifying the underlying causes of non-conformities to prevent recurrence.

- Action Planning: Developing plans to address identified issues and opportunities for improvement.

Aligning Continual Improvement with Quality Objectives

Continual improvement is an ongoing effort to enhance the QMS, and it aligns with quality objectives by:

- Ensuring that improvement activities are directly linked to your organisation’s strategic goals.

- Fostering a culture of excellence where every employee is engaged in the process of making improvements.

- Utilising feedback from internal audits to set actionable and measurable improvement targets.

Emergency Preparedness and Resilience

In the landscape of ISO 9001:2015, emergency preparedness is not just a precaution; it’s a strategic imperative. Clause 8 mandates the integration of risk management and contingency planning into your Quality Management System (QMS), ensuring that your organisation can swiftly respond to unexpected events without compromising on quality.

Essential Strategies for Contingency Planning and Risk Management

Effective contingency planning hinges on a proactive approach. At ISMS.online, we guide you through essential strategies that include:

- Risk Assessment: Identifying potential emergencies and their impact on operations.

- Response Planning: Developing clear, actionable plans for different scenarios.

- Resource Allocation: Ensuring that the necessary resources are available to handle emergencies.

Building Operational Resilience

Operational resilience is the backbone of ISO 9001 compliance. It ensures that your organisation can absorb and adapt to disruptions while maintaining service quality. To build resilience, you should:

- Conduct regular drills to test and refine your emergency response plans.

- Review and update your plans to reflect changes in your operational environment.

Best Practices for Emergency Preparedness

Best practices in emergency preparedness are integral to a robust QMS. They include:

- Employee Training: Equipping your staff with the knowledge to handle emergencies effectively.

- Communication Protocols: Establishing clear lines of communication for swift action.

Ensuring Preparedness for Operational Disruptions

To ensure your organisation is well-prepared for operational disruptions, we provide tools and frameworks that help you:

- Document your emergency procedures for easy access and reference.

- Integrate risk management into your everyday operations, making preparedness a part of your organisational culture.