ISO 9001, Clause 8.7, Explained

When you’re tasked with managing quality within your organisation, identifying and documenting nonconforming outputs is a critical step in maintaining the standards set by ISO 9001:2015, Clause 8.7. Nonconforming outputs are essentially results that do not meet the predefined specifications or customer requirements. The initial steps for identifying these outputs involve a thorough inspection process, where our platform, ISMS.online, can provide systematic guidance.

Initial Steps for Identification

To begin with, establish clear criteria for what constitutes a nonconformity in your products or services. This will involve understanding the specifications and requirements that your outputs must meet. Once criteria are set, conduct regular inspections and reviews to catch any deviations early on.

Documentation According to ISO Standards

Proper documentation is not just a requirement; it’s a cornerstone of quality management. Record every nonconformity in detail, including the nature of the deviation, the product or service affected, and the time and place of identification. This is where a Non-Conformance Action Log (NCR) becomes indispensable.

Essential Information in NCR

An effective NCR should include:

- A unique identifier for each nonconformity

- A description of the nonconformity

- The affected product or service

- The date of detection

- Actions taken to address the nonconformity

Supporting Continuous Improvement and Accountability

By meticulously documenting nonconformities, you create a data-driven approach to continuous improvement. This documentation helps in tracing issues back to their root causes, facilitating corrective actions, and preventing future occurrences. With ISMS.online, you can ensure that your documentation is not only compliant with ISO standards but also supports accountability and ongoing enhancement of your quality management system.

Book a demoActions for Nonconformities

Upon the detection of a nonconformity, immediate action is paramount to prevent further impact on production and customer satisfaction. These actions are a direct response to the identified issue and serve as the first line of defence in your quality management system.

Responding to Nonconformities

The initial response to a nonconformity involves isolating the affected product or service to prevent it from reaching the customer. This is followed by assessing the scope of the issue to understand its impact. You must then inform relevant stakeholders, including customers if necessary, about the nonconformity and the steps being taken to address it.

Maintaining Customer Satisfaction

By taking swift and transparent action, you demonstrate a commitment to quality and customer care. This responsiveness is crucial in maintaining trust and can often mitigate dissatisfaction.

The Role of Segregation

Segregation is a critical control measure that ensures nonconforming outputs are contained and do not mix with conforming ones. It is a physical or systemic action that prevents the use or delivery of nonconforming products or services.

ISMS.online’s Role in Immediate Response

Our platform, ISMS.online, streamlines the immediate response process with automated alerts and workflow management. This ensures that the right people are notified and corrective actions are initiated without delay, maintaining the integrity of your quality management system.

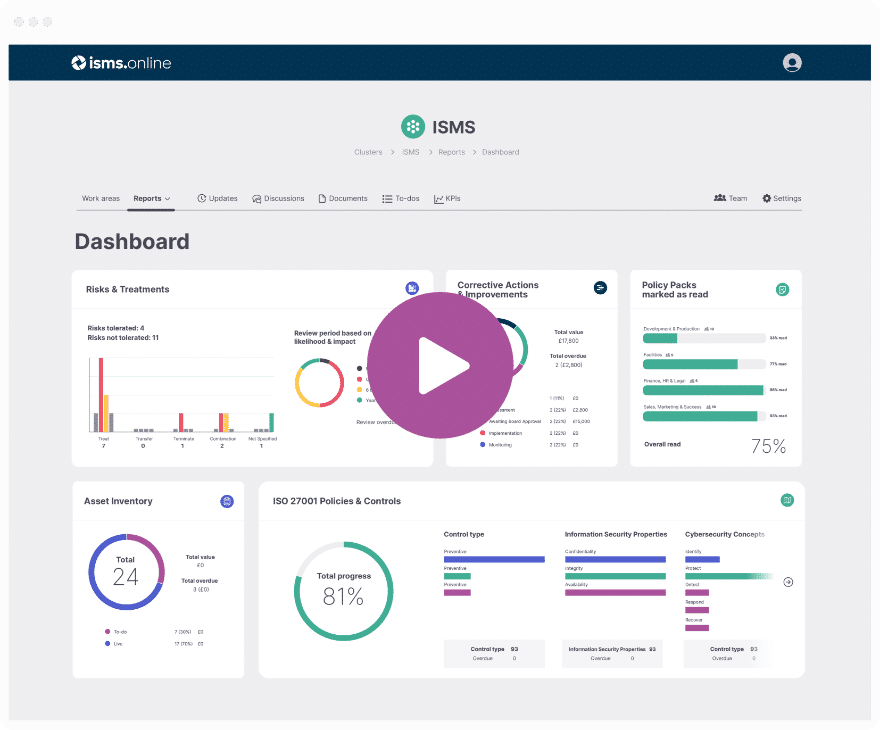

Get an 81% headstart

We've done the hard work for you, giving you an 81% Headstart from the moment you log on.

All you have to do is fill in the blanks.

Review and Decision-Making Process

The review and decision-making process for nonconforming outputs is a structured approach that ensures any deviations from quality standards are managed effectively and in alignment with your organisation’s quality policy.

Assessing the Impact of Nonconformities

When a nonconforming output is identified, it’s crucial to assess its impact on both the product quality and customer satisfaction. This assessment involves:

- Reviewing the extent of the nonconformity

- Determining potential effects on subsequent processes or products

- Evaluating the implications for customer use and satisfaction

Criteria for Release

A nonconforming output may be released under concession if it meets specific criteria, which typically include:

- The nonconformity does not affect the product’s or service’s intended use

- The deviation is acceptable to the customer or end-user

- There are assurances that the nonconformity will not lead to future issues

Decision-Making Authorities

Decisions regarding nonconforming outputs are typically made by personnel with designated authority within the quality management system. This may include roles such as:

- Quality Managers

- Process Owners

- Senior Management

Aligning with Quality Policy

Our platform, ISMS.online, supports your decision-making process by ensuring that all actions taken are in line with your organisation’s quality policy and documented accordingly. We provide tools that help you to:

- Document the rationale for decisions

- Record any concessions granted

- Ensure traceability and accountability within the QMS

Corrective Actions and Preventive Measures

In the realm of quality management, distinguishing between corrective and preventive actions is essential for continuous improvement. Corrective actions are reactive measures taken in response to the detection of nonconforming outputs, while preventive actions are proactive steps designed to eliminate the causes of potential nonconformities before they occur.

Implementing Corrective Actions

To implement effective corrective actions, you should:

- Investigate the root cause of the nonconformity.

- Develop a plan to rectify the issue and prevent recurrence.

- Execute the corrective actions and monitor their effectiveness.

Contribution to Product and Service Improvement

Corrective actions are integral to product and service improvement as they:

- Address specific issues to prevent their recurrence.

- Enhance the robustness of your quality management processes.

- Lead to improvements in product quality and service delivery.

ISMS.online’s Support in Corrective Action Management

At ISMS.online, we understand the importance of a structured approach to corrective actions. Our platform aids in managing this process by providing:

- Templates for documenting corrective actions.

- Workflow tools to assign tasks and track progress.

- Analytical features to evaluate the effectiveness of the actions taken.

By leveraging our services, you ensure that your corrective actions are not only compliant with ISO 9001:2015 but also contribute to the overarching goal of quality excellence.

Manage all your compliance in one place

ISMS.online supports over 100 standards

and regulations, giving you a single

platform for all your compliance needs.

Responsibility in Nonconformity Management

In the landscape of a Quality Management System (QMS), the authority for action on nonconformities must be clearly defined. This clarity ensures that when nonconformities arise, there is no ambiguity about who is responsible for managing them.

Defining Authority within a QMS

Authority within a QMS is typically assigned to specific roles, such as:

- Quality Managers, who oversee the QMS and ensure compliance with ISO 9001:2015.

- Process Owners, who are responsible for individual processes within the QMS.

- Senior Management, who provide the resources and support necessary for effective nonconformity management.

Responsibilities of Personnel

Personnel involved in managing nonconformities have several key responsibilities:

- Identifying and documenting nonconformities as they occur.

- Assessing the impact of nonconformities on operations and customer satisfaction.

- Implementing corrective actions and monitoring their effectiveness.

Enhancing System Accountability

A clear delineation of authority and responsibility enhances system accountability by:

- Ensuring that actions are taken promptly and effectively.

- Creating a transparent environment where everyone knows their role.

- Facilitating communication and coordination among different departments.

Tools for Role Definition and Communication

At ISMS.online, we provide tools that assist in defining and communicating these roles, such as:

- Customizable templates for role descriptions and responsibilities.

- Access control features to ensure that only authorised personnel can take certain actions.

- Communication platforms to facilitate collaboration and information sharing.

By utilising these tools, you can ensure that your QMS operates smoothly and that nonconformities are managed with the utmost efficiency and accountability.

Auditing Nonconformities for Continuous Improvement

Auditing is a critical component of the continuous improvement process within a Quality Management System (QMS). It involves a detailed examination of procedures and records to ensure nonconforming outputs are effectively managed. However, this process can be complex due to the dynamic nature of production and service delivery.

Complexities in Auditing Nonconforming Outputs

Auditors face several challenges when assessing nonconforming outputs:

- Volume and Variety: The sheer number of nonconformities and their varying nature can be overwhelming.

- Continuous Production: In environments with continuous production, capturing every nonconformity requires diligent monitoring.

- Audit Trail: Establishing a comprehensive audit trail is essential but can be intricate, especially across multiple functions.

Focus on Quality Control

During audits, the focus on quality control for nonconforming outputs includes:

- Verification of the identification process for nonconformities.

- Assessment of the effectiveness of corrective actions taken.

- Review of documentation and records for completeness and accuracy.

Importance of an Audit Trail

An effective audit trail is crucial as it:

- Provides a historical record of nonconformities and actions taken.

- Ensures traceability and accountability within the QMS.

- Supports risk management and regulatory compliance.

Streamlining with ISMS.online

Our platform, ISMS.online, streamlines the audit process by offering:

- Integrated tools for real-time monitoring and reporting.

- Automated workflows to ensure consistent documentation.

- centralised data storage for easy access during audits.

By leveraging ISMS.online, you can simplify the complexities of auditing nonconforming outputs, ensuring continuous improvement and compliance with ISO 9001:2015.

Compliance doesn't have to be complicated.

We've done the hard work for you, giving you an 81% Headstart from the moment you log on.

All you have to do is fill in the blanks.

Managing Nonconformities

In ISO 9001, the approach to managing nonconforming services requires a nuanced understanding, as the intangible nature of services presents unique challenges compared to physical products.

Identifying Nonconforming Services

Nonconforming services are typically identified through customer feedback, service delivery monitoring, and performance evaluations. Unlike products, services often involve real-time interaction with customers, which means:

- Immediate detection is possible during service provision.

- Rapid response is crucial to rectify any deviations from service standards.

Impact on Customer Satisfaction

The impact of nonconforming services on customer satisfaction can be significant, as services are experienced in real-time. Nonconformities in services can lead to:

- Immediate customer dissatisfaction

- Damage to the organisation’s reputation

- Potential loss of business

Conducting Impact Analysis

To analyse the impact of nonconforming services, consider:

- Customer feedback to gauge immediate reactions.

- Service recovery strategies to address and mitigate issues.

- Long-term effects on customer loyalty and trust.

Role of Design and Development

Design and development play a preventative role by:

- Establishing clear service delivery processes

- Incorporating customer feedback into service design

- Training staff to ensure consistent service quality

At ISMS.online, we support you in managing nonconforming services by providing tools for real-time monitoring, feedback analysis, and service improvement planning. Our platform ensures that you can address nonconformities effectively and maintain the high level of customer satisfaction that is essential for your business success.

Further Reading

Scalable Solutions for Diverse Organisational Needs

In the pursuit of quality management excellence, the adaptability of tools and templates to various organisational contexts is paramount. At ISMS.online, we recognise that each organisation is unique, and therefore, scalability and customisation are at the heart of our solutions.

Tailoring Templates and Tools

To ensure that our templates and tools fit your organisation like a glove, we:

- Offer customisable templates that can be modified to reflect your specific processes and procedures.

- Provide flexible tools that can be scaled up or down depending on the size and complexity of your operations.

Effectiveness in Managing Nonconforming Outputs

An effective template or tool for managing nonconforming outputs should:

- Clearly define roles and responsibilities.

- Include step-by-step processes for identification, documentation, and correction.

- Facilitate easy tracking and reporting of nonconformities.

Ensuring Scalability and Applicability

To ensure that our resources remain scalable and applicable, we:

- Regularly update our offerings based on the latest ISO standards and best practices.

- Incorporate feedback from a diverse range of clients to enhance functionality.

ISMS.online’s Scalable Quality Management Solutions

Our platform provides scalable solutions that:

- Integrate seamlessly with your existing processes.

- Support a holistic approach to quality management.

- Offer dynamic tools for risk management and continuous improvement.

By partnering with ISMS.online, you’re equipped with the resources necessary to manage nonconforming outputs effectively, regardless of your organisation’s size or sector.

Enhancing Quality Management Systems with Integrated Tools

In the quest for quality excellence, integrated tools are not just a luxury; they are a necessity for a robust Quality Management System (QMS). At ISMS.online, we understand that the integration of tools can streamline processes, enhance efficiency, and provide a cohesive approach to managing quality.

Benefits of App Integration in Operational Planning

App integration brings a multitude of benefits to operational planning and provision:

- Centralises data, making it easily accessible for decision-making.

- Automates workflows, reducing the potential for human error.

- Facilitates communication between different departments, ensuring everyone is aligned with the quality objectives.

Efficient Document Management

Efficient document management is critical for controlling nonconforming outputs. It ensures that:

- All records are up-to-date and readily available for audits.

- Traceability is maintained from identification to resolution of nonconformities.

- Compliance with ISO 9001:2015 is easier to demonstrate.

Dynamic Risk Management Tools

Our dynamic risk management tools are designed to help you proactively address threats and seize opportunities:

- Risk assessments can be conducted with ease, allowing for timely identification of potential issues.

- Action plans can be developed and tracked through the platform.

- Real-time monitoring ensures that you are always aware of the current risk landscape.

By leveraging the integrated tools provided by ISMS.online, you’re not just managing nonconforming outputs; you’re elevating your entire QMS to a level of operational excellence that meets and exceeds ISO 9001:2015 standards.

Ensuring Compliance and Certification Readiness

Achieving ISO 9001 certification is a significant milestone for any organisation committed to quality management excellence. A pre-configured Quality Management System (QMS) serves as a foundational framework that aligns with ISO standards, ensuring that all necessary processes and documentation are in place for successful certification.

Role of a Pre-Configured QMS

A pre-configured QMS, like the one we offer at ISMS.online, simplifies the path to ISO 9001 certification by:

- Providing a structured approach to quality management.

- Ensuring that all ISO requirements are addressed comprehensively.

- Reducing the time and resources needed to develop a QMS from scratch.

Guided Certification Process

Our guided certification process, the Assured Results Method (ARM), ensures compliance and successful outcomes by:

- Offering step-by-step guidance through the certification journey.

- Clarifying ISO 9001 requirements and how to meet them.

- Helping to avoid common pitfalls that can delay certification.

Virtual Coaching and Support

To further support your understanding of ISO nuances, we provide:

- Virtual coaching sessions to address specific questions and challenges.

- Expert insights into the practical application of ISO standards.

ISMS.online’s Assistance for Certification Preparation

At ISMS.online, we are dedicated to assisting organisations in preparing for ISO 9001 certification by:

- Offering a comprehensive suite of tools to manage your QMS effectively.

- Providing templates and resources that are aligned with ISO requirements.

- Ensuring that you have a clear roadmap to certification readiness.