Requirements of ISO 9001, Clause 8.1

When you’re delving into the specifics of ISO 9001:2015, Clause 8.1 stands out as a cornerstone for operational planning and control. This clause lays down the foundation for how an organisation should plan, implement, and control the processes needed to meet service and product requirements, and to implement the actions determined by risk and opportunities.

Specific Requirements of Operational Planning and Control

Clause 8.1 mandates that your processes align with the overall business strategy, ensuring that the quality management system (QMS) is effectively integrated into your business operations. It requires you to plan and control your operations meticulously, considering both the desired outcomes and the potential risks and opportunities.

Ensuring Consistency and Uniformity

The requirements of Clause 8.1 are designed to ensure that your QMS is consistent and uniform. This means that whether you’re in manufacturing, healthcare, or any other industry, the clause provides a framework that can be universally applied, ensuring that quality management processes are standardised across the board.

Facilitating Across Industry Sectors

By adhering to the standards set out in Clause 8.1, organisations facilitate interoperability. This is because the clause’s guidelines are recognised internationally, allowing different sectors to work together more seamlessly, sharing a common language of quality.

Clause 8.1's Role in QMS Effectiveness

At its core, Clause 8.1 is integral to the effectiveness of a QMS. It ensures that operational processes are not only planned and carried out under controlled conditions but also reviewed and adjusted in light of process performance and outputs, which is essential for continuous improvement.

By following these guidelines, you can ensure that your operational planning and control processes are robust and capable of driving your organisation towards its quality objectives. And with our platform, ISMS.online, we provide the tools and support you need to implement these requirements effectively.

Book a demoIntegrating Risk Management in Operational Planning

Incorporating risk and opportunity management into your operational planning is a strategic approach that aligns with the ISO 9001:2015 standard. It’s about anticipating potential challenges and seizing opportunities that can lead to improved quality and performance.

Benefits of a Risk-Based Approach

A risk-based approach to operational control allows you to proactively address uncertainties and ensure that your quality objectives are met. It enhances the ability to make informed decisions and prioritise actions that contribute to the overall effectiveness and efficiency of your QMS.

ISMS.online and Risk Integration

At ISMS.online, we understand the importance of integrating risk and opportunity management into your operational planning. Our platform is designed to help you identify, assess, and manage risks with ease, ensuring that you’re always one step ahead.

Documentation for Risk Management

To evidence your risk management integration, you’ll need to maintain clear and comprehensive documentation. This includes records of risk assessments, mitigation plans, and any changes made to operational processes as a result of risk analysis. With ISMS.online, all your documentation can be securely managed and easily accessed, supporting your commitment to continuous improvement and compliance.

Get an 81% headstart

We've done the hard work for you, giving you an 81% Headstart from the moment you log on.

All you have to do is fill in the blanks.

Documentation and Evidence of Control

Proper documentation is the backbone of demonstrating operational planning and control within your Quality Management System (QMS). It serves as evidence that your processes are planned, implemented, and controlled according to the ISO 9001:2015 standards.

Essential Documentation for Operational Control

To comply with Clause 8.1, you’re required to maintain the following types of documentation:

- Operational Plans: Detailed outlines of how you intend to execute and monitor your processes.

- Control Records: Evidence of the criteria for acceptance, checks performed, and the results of these checks.

- Change Management Logs: Documentation of planned changes and how these changes are managed and communicated within the organisation.

Contribution to Information Security and Process Maintenance

Proper documentation ensures that sensitive information is protected and that operational processes are consistently followed and maintained. It provides a clear audit trail for compliance officers and auditors to follow, ensuring that every step of your operational planning and control is transparent and verifiable.

The Role of Document Management Systems

A robust document management system is crucial for maintaining ISO compliance. It allows for:

- Secure storage and easy retrieval of documents.

- Tracking of revisions and approvals.

- Streamlined sharing and collaboration across the organisation.

ISMS.online: Streamlining Your Documentation

At ISMS.online, we offer a comprehensive solution for managing your QMS documentation. Our platform enables you to:

- Securely store all your documentation in one place.

- Easily update and share documents while maintaining version control.

- Demonstrate compliance with ISO 9001:2015 through organised and accessible records.

By leveraging our platform, you ensure that your documentation is not only up to date and compliant but also contributes to the overall efficiency and security of your operational planning and control processes.

Customer-Centric Operational Planning

At the heart of ISO 9001:2015 is the principle of customer focus, which should be a primary driver in your operational planning and control. Understanding and meeting customer requirements are not just about compliance; it’s about building the foundation for continual improvement and customer satisfaction.

Methods for Capturing Customer Feedback

To ensure that your operational planning is customer-centric, you must have effective methods in place to capture customer feedback. This can include:

- Surveys and Questionnaires: Regularly engaging with customers to solicit their input on your products and services.

- Feedback Channels: Providing multiple avenues for customers to communicate their needs and concerns, such as support hotlines, email, or social media platforms.

Integrating Customer Communication into Operations

Incorporating customer feedback into your operational processes is crucial. This integration can take the form of:

- Review Meetings: Regularly scheduled sessions where customer feedback is discussed and actioned.

- Change Implementation: Adjusting operational plans to address customer needs and enhance satisfaction.

Consequences of Neglecting Customer Requirements

Ignoring customer requirements in operational planning can lead to:

- Dissatisfaction: Customers may feel their needs are not being met, leading to negative reviews and loss of business.

- Non-Compliance: Failing to meet customer requirements can result in non-compliance with ISO 9001:2015, impacting your certification status.

At ISMS.online, we provide the tools and support to help you integrate customer focus into every aspect of your operational planning and control, ensuring that you not only meet but exceed customer expectations.

Manage all your compliance in one place

ISMS.online supports over 100 standards

and regulations, giving you a single

platform for all your compliance needs.

Change Management Within Operational Control

Effective change management is pivotal in ensuring that your operational planning and control remain agile and responsive to both planned and unforeseen changes. It’s about maintaining the integrity and quality of your services throughout transitions.

Managing Planned and Unintended Changes

To manage changes effectively, you should:

- Develop a Change Management Plan: Outline the steps and measures to manage changes, including communication strategies and timelines.

- Conduct Impact Assessments: Evaluate the potential effects of changes on existing operations and quality objectives.

- Implement Change Control Procedures: Establish protocols to authorise and document changes, ensuring traceability and accountability.

Ensuring Control Over Outsourced Processes

For outsourced processes, control can be maintained by:

- Defining Clear Contracts: Specify quality requirements and responsibilities in agreements with third-party providers.

- Conducting Regular Audits: Assess the performance and compliance of outsourced processes to ensure they meet your standards.

Role of Change Management in Service Quality

Change management safeguards service quality by:

- Preventing Service Disruption: By planning changes carefully, you minimise the risk of service interruptions.

- Maintaining Compliance: Ensuring that changes are made within the framework of ISO 9001:2015 keeps your operations compliant.

ISMS.online: Facilitating Change Management

At ISMS.online, we provide a robust platform that supports change management by:

- Documenting Changes: Our system allows you to record and track changes, ensuring a clear audit trail.

- Communicating Effectively: With integrated communication tools, you can ensure that all stakeholders are informed and engaged throughout the change process.

Aligning Operational Control with Quality Objectives

Operational controls are not standalone elements; they are integral to achieving your organisation’s quality objectives. At ISMS.online, we emphasise the alignment of these controls with your overarching goals to ensure that every operational activity contributes to quality and excellence.

Best practices for Setting Quality Objectives

To align operational controls with quality objectives, consider the following best practices:

- Define Clear Objectives: Establish specific, measurable, achievable, relevant, and time-bound (SMART) quality objectives that reflect your strategic goals.

- Regular Reviews: Conduct periodic reviews of your quality objectives to ensure they remain aligned with changing business needs and customer expectations.

Contribution to Continual Improvement

Operational control is a dynamic process that drives continual improvement by:

- Monitoring Performance: Use Key Performance Indicators (KPIs) to track the effectiveness of operational controls.

- Adapting Processes: Adjust operational controls in response to performance data, ensuring ongoing enhancement of quality.

Challenges in Alignment

Challenges you might face include:

- Evolving Business Needs: Staying responsive to rapid changes in the business environment while maintaining alignment with quality objectives.

- Balancing Innovation and standardisation: Innovating within the constraints of standardised processes to improve quality without compromising compliance.

Remember, operational control is about steering your organisation towards its quality goals. With our platform, you have the tools to manage this alignment effectively, ensuring that your operational planning is not just compliant, but also a catalyst for excellence.

Compliance doesn't have to be complicated.

We've done the hard work for you, giving you an 81% Headstart from the moment you log on.

All you have to do is fill in the blanks.

Auditing Operational Planning and Control Processes

Auditing is a critical component of the ISO 9001:2015 framework, serving as a tool for you to verify the effectiveness of your operational planning and control. It provides an objective lens through which the performance of these processes can be assessed, ensuring that they align with the established quality objectives and compliance requirements.

The PDCA Approach in Auditing

The Plan-Do-Check-Act (PDCA) cycle is deeply embedded in the auditing process, providing a structured approach for continuous improvement:

- Plan: Establish the audit objectives, scope, and criteria.

- Do: Conduct the audit to collect evidence.

- Check: analyse the findings and compare them against the audit criteria.

- Act: Implement corrective actions to address any non-conformities.

Staying Informed on Auditing Standards

As a compliance officer, it’s essential to stay abreast of the latest changes in auditing standards. These changes can impact how audits are planned, executed, and reported, and may influence the way you manage your QMS.

Streamlining Audits with ISMS.online

At ISMS.online, we provide a platform that simplifies the auditing process:

- centralised Documentation: Easily access all necessary documents for auditing in one secure location.

- Audit Planning Tools: Plan and schedule audits with integrated calendars and notification systems.

- Action Tracking: Monitor the implementation of corrective actions and ensure timely resolution of findings.

By leveraging our platform, you can ensure that your auditing process is not only compliant with the latest standards but also efficient and effective, contributing to the overall robustness of your operational planning and control.

Further Reading

Implementing ISO 9001:2015 Clause 8.1 with Technology

Leveraging technology is a game-changer in the realm of operational planning and control. It not only streamlines the implementation of ISO 9001:2015 Clause 8.1 but also enhances the efficiency and accuracy of your Quality Management System (QMS).

Advantages of Pre-configured Quality Management Systems

Pre-configured QMS platforms, like the one we offer at ISMS.online, provide a structured and standardised approach to implementing operational planning and control. These systems come with built-in best practices, reducing the time and effort required to achieve compliance. They also offer:

- Consistency: Standardised processes across the organisation.

- Compliance: Built-in compliance checks to ensure all operations meet ISO standards.

- Efficiency: Streamlined workflows that save time and reduce the potential for human error.

Enhancing Operations with App Integrations

App integrations bring a new level of functionality to operational planning and control. By connecting tools like Jira, Salesforce, and Zapier, you can:

- Automate Tasks: Reduce manual workloads through automation.

- Improve Communication: Ensure seamless information flow between different departments and software.

- Enhance Visibility: Gain a comprehensive view of operations and performance metrics.

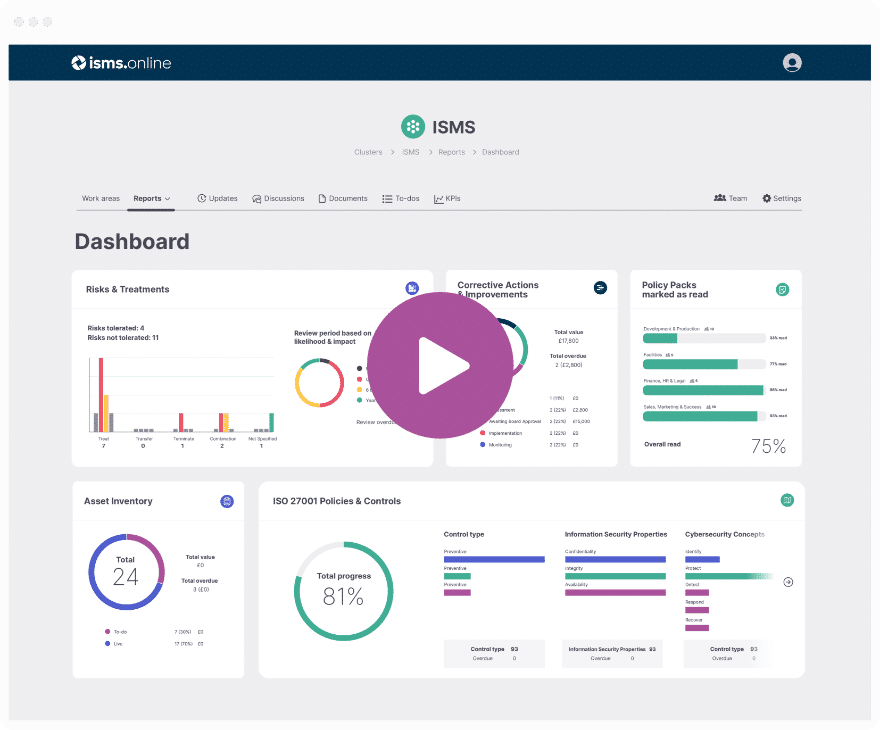

Virtual Support and Progress Tracking with ISMS.online

Our platform, ISMS.online, is designed to support you every step of the way. With features like the Virtual Coach and dynamic risk tools, you can:

- Receive Guidance: Access expert advice on implementing Clause 8.1.

- Track Progress: Monitor your advancement towards compliance with real-time dashboards.

- Stay Organized: Keep all your documentation and evidence in one secure, accessible place.

By embracing technology and utilizing platforms like ISMS.online, you’re not just complying with ISO 9001:2015; you’re setting your organisation up for a future of continual improvement and success.

Managing Resources and Timelines in Production Planning

Effective production planning is a critical component of operational planning and control as outlined in ISO 9001:2015 Clause 8.1. It requires a strategic approach to resource allocation and timeline management to ensure that your processes are efficient and your products and services meet quality standards.

Key Considerations for Resource Allocation

When allocating resources, you must consider:

- Capacity: Assess the capacity of your resources to ensure they can meet production demands.

- Skill Level: Match the skills of your workforce with the complexity of the tasks at hand.

- Availability: Ensure that the necessary resources are available when needed to avoid bottlenecks.

Impact of Timelines on Operational Efficiency

Timelines directly influence the efficiency and effectiveness of your operational control by:

- Setting Clear Deadlines: Deadlines help to prioritise tasks and manage workflow.

- Enabling Progress Tracking: Timelines allow you to monitor progress and make adjustments as needed.

Criteria for Successful Production Planning

Success in production planning can be evaluated using criteria such as:

- Adherence to Schedule: Meeting set deadlines for production milestones.

- Resource Utilization: Efficient use of resources without overuse or waste.

- Quality Metrics: Meeting predefined quality standards and customer satisfaction levels.

Contribution to Product and Service Quality

A well-managed production plan ensures:

- Consistency: Uniformity in product and service quality.

- Compliance: Adherence to ISO standards and customer requirements.

At ISMS.online, we provide tools and guidance to help you manage your resources and timelines effectively, ensuring that your production planning supports the overall quality objectives of your organisation.

Ensuring Compliance Through Internal Audits

Internal audits are a vital mechanism within your Quality Management System (QMS) to ensure that operational planning and control processes comply with ISO 9001:2015 standards. At ISMS.online, we recognise the importance of these audits in maintaining the integrity of your QMS.

Verifying Compliance with Operational Planning and Control

Internal audits serve as a check to verify that your operational planning and control processes are not only established but also effectively implemented and maintained. They help you to:

- Assess Conformity: Determine if processes align with the planned arrangements set out in your QMS.

- Identify Gaps: Uncover areas where your processes may not meet ISO 9001:2015 requirements.

Role of Internal Auditing in Risk Management

A robust internal audit process plays a crucial role in risk management by:

- Evaluating Risk Controls: Ensuring that risk treatment plans are properly executed and effective.

- Facilitating Communication: Providing a platform for discussing risk findings and necessary improvements.

Driving Improvements in Operational Planning

Organisations can leverage internal audits to drive continual improvement by:

- Informing Decision-Making: Using audit findings to make informed decisions about process changes.

- Promoting Best Practices: Sharing insights from audits to foster a culture of excellence and compliance.

Essential Elements of an Internal Audit Process

Key elements of a successful internal audit process include:

- Qualified Auditors: Personnel with the necessary skills and impartiality to conduct audits.

- Structured Methodology: A clear audit plan, criteria, and methods to guide the audit process.

- Actionable Reporting: Clear documentation of audit findings and recommendations for corrective actions.

By integrating these elements into your internal audit process, you ensure that your operational planning and control are not only compliant but also positioned for ongoing improvement and success.