The ISO 9001 standard, internationally recognised for its focus on quality management, offers key processes that can be gracefully incorporated into an organisation’s operations. By constructing a Quality Management System (QMS) based on ISO 9001, an organisation ensures that quality permeates all its operational sections.

A major benefit of a QMS rooted in ISO 9001 is the cultivation of an enduring improvement culture. This approach demands that processes undergo systematic reviews, which inevitably highlight areas ready for refinement–ranging from minimising manufacturing waste to accelerating customer service protocols. The result? A consistent cycle of organisational improvement.

Possession of an ISO 9001 certification provides an edge for organisations in today’s tough business environment. It introduces them to prospects as an enterprise that’s resolutely committed to quality—a trait virtually irresistible to potential clients and collaborators.

The ISO 9001 standard is a widely acknowledged quality management tool applicable across multiple business sectors. The use of the term ‘standard’ herein adheres to the common terminology used by auditors, certified organisations, and international standards bodies to describe ISO 9001.

The essence of quality management is at the heart of the ISO 9001 standard. It is more than a suggested guideline; it’s an all-inclusive standard aimed at managing and enhancing service quality across various industries.

Though the ISO 9001 standard is often linked with the manufacturing sector because of its broad-ranging application in this area, its sphere of influence touches many other sectors too. Information technology (IT), healthcare, finance, and education are just a few sectors where this standard is similarly integral.

The application of ISO 9001 maintains a consistent underlying objective – enhancing process quality, increasing customer satisfaction, and overall organisational performance enhancement. ISO 9001 thus validates industries’ commitment to continual improvement and a desire to meet and exceed client needs across all sectors.

Request a quote

The process-oriented structure of ISO 9001 emphasises the crucial role each organisation’s specific processes play in achieving quality outcomes. By bypassing the variation in quality that can occur when tasks are performed without standardised guidelines, this approach ensures consistency and efficiency, thus promoting customer satisfaction and continual improvement.

Key Elements of ISO 9001 Quality Management System

A Quality Management System, as prescribed under ISO 9001, typically comprises various key components. These components, when functioning cohesively, help establish an environment conducive to ongoing improvement and customer satisfaction. Such components include:

Adherence to these fundamental elements enables businesses to construct a robust Quality Management System, aligning with customer expectations and regulatory requirements. More than just a standard, the process-oriented ISO 9001 portrayal empowers organisations with the framework to consistently deliver superior quality products and services that meet customer specifications and regulatory stipulations.

In the initial phase, an organisation must create a clear statement indicating the organisation’s commitment to quality. Carrying out this commitment goes beyond crafting a well-worded promise; it involves formulating an actionable plan strategically designed to realise those defined quality objectives.

Creating streamlined and efficient operations involves the defining of roles, responsibilities, and process descriptions. However, it’s also crucial that we recognise and manage interrelated processes as a cohesive system, ensuring a seamless workflow and enhanced productivity.

To guarantee the delivery of quality products and services, we implement rigid control measures that help detect nonconformities at the earliest stage. Early detection plays a crucial role in allowing us to institute timely preventive and corrective actions, mitigating any adverse effects on the product or service quality.

Performance analysis necessitates comprehensive and accurate data collection. Following ISO 9001:2015 requirements, we specify when, what, and how monitoring and measuring activities should be carried out to optimise data analysis and ultimately fuel an informed decision-making process.

Adhering to ISO 9001’s principle of continuous improvement, the standard encourages organisations to perpetually seek ways to enhance all aspects of the business. This practice involves an organisational culture committed to unceasing, comprehensive, and proactive enhancement of procedures, processes, and performance.

In order to ensure the document’s ongoing relevance and credibility, vigilant updating and validating of the information are practised. This commitment to ‘current relevance’ ensures content conforms to industry developments and the evolving ISO 9001 standards.

The journey to perfecting quality management is continuous, each step woven into the fabric of the organisation’s DNA. Each phase seamlessly advancing to the next, establishing a steady progression that mutually enhances organisational performance and meets ISO 9001 quality measures. Your commitment to tracking and achieving these benchmarks drives sustainability and success within your organisation.

Book a tailored hands-on session based on your needs and goals.

The first step in this process is for the organisation to establish a QMS. This pivotal process involves identifying the core business operations, along with defining the company policy and objectives. Concurrently, the QMS scope and procedural standards are set in place, laying a solid foundation for efficiency and quality management.

A crucial aspect of quality management is the Plan-Do-check-Act (PDCA) cycle. Integrated within the establishment of the QMS, this systematic, iterative method aids organisations in improving operational procedures and ensures a consistent focus on quality improvement.

The next phase entails the organisation conducting an internal audit of the QMS. To ensure rigorous and accurate assessment of the operational processes, a qualified auditor is appointed. The auditor’s expert insights help identify instances of non-conformity and aid in making necessary improvements before the external audit stage.

Subsequent to the internal audit is an external audit, executed by a third-party certification body. The auditors, assigned by the certification body, play a critical role in evaluating the organisation’s readiness and compliance with the ISO 9001 standard.

Quality management practices are established pillars of operational strategy across industries today, and ISO 9001 certification forms the bedrock. A commitment to ISO 9001 reverberates operational efficiency, improved customer satisfaction, and a streamlined regulatory compliance process.

The ISO 9001 certification is far more than just a quality assurance checkmark. It serves as a propellant for operational efficiency, a magnifier of customer satisfaction, and a facilitator for seamless regulatory compliance.

Compliance officers might find the certification beneficial in strategically handling regulatory procedures. emphasising its role, the relatively competitive market makes the ISO 9001 certification a significant asset, not an absolute necessity for organisations. It’s the strategic utilisation of the certification that truly capitalises on its potential benefits and aids in driving business growth.

We can’t think of any company whose service can hold a candle to ISMS.online.

Maintaining ISO 9001 certification necessitates continuous improvement and commitment, ensuring your organisation’s Quality Management System (QMS) effectively meets customer and regulatory requirements. As an integral part of ISO 9001, we aim to provide you with a practical understanding needed to effectively maintain this certification in compliance with its specifications.

Four Strategic Steps towards Sustaining the ISO 9001 Certification

While maintaining an ISO 9001 certification presents its unique challenges, recognising them early and implementing proactive steps minimises their impact. Here are some ISO 9001 challenges and their solutions:

ISO 9001 audits are vital to validate the efficacy of an organisation’s Quality Management System (QMS). They ensure the existing QMS is in alignment with the organisation’s quality policy and is compliant with ISO 9001 standards. Starting with the selection of auditors and establishment of audit objectives, the process then sees a preliminary review of the QMS documentation. This initial Document Review sets the audit trail, aiding in the planning of the audit and identification of areas needing closer examination.

Post this, a Preliminary Meeting between auditors and the audited party’s representatives takes place. This meeting discusses the audit procedure, schedules, requirements, and any potential areas of concern. Such proactive communication promotes transparency and familiarises the parties to the audit process.

The subsequent Execution of the Audit involves process observation, personnel interviews, and record examination, in turn measuring the conformance of the QMS. The evidence gathered through these steps contributes to the final audit judgement.

To ensure a successful audit, auditors must have unrestricted access to all relevant documentation and personnel for the necessary interviews and data collection. Pertinent documents could include operational procedures, guidelines, standards, and related records.

Post-audit activities principally include Audit Reporting and Audit Follow-up and Surveillance. The former involves creating a detailed report of the audit findings, highlighting any areas requiring improvement. The latter monitors the organisation’s actions undertaken to rectify non-compliance.

The ISO 9001 auditing process is, thus, not just an activity of inspection, but a powerful tool enhancing system integrity, propelling improvement, and boosting customer satisfaction. It necessitates auditors to maintain open communication and a cooperative approach with the audited entity, using the audit findings as a stepping stone towards continual improvement. Going beyond merely identifying non-compliance, a successful audit also offers extensive guidance and improvement solutions.

ISO 9001 puts a strong emphasis on continuous improvement, requiring organisations to continually elevate their operations to enhance their overall performance. Notably, ISO 9001:2015 clause 10 “Improvement”, outlines the concepts of nonconformity, corrective action along with continual improvement.

The PDCA Cycle (Plan-Do-check-Act), forms a pragmatic approach to continuous improvement within an ISO 9001 QMS (Quality Management System). This management methodology proves crucial to achieving regular and cyclic improvement in an organisation.

Findings from quality audits, both internal and external, provide organisations with areas of discrepancies and opportunities for improvement. The insights from these audits need meticulous examination, followed by prompt and effective corrective actions. For systematic tracking of audit activities, we recommend specialised tools like ISMS.online.

Continuous service refinement can be achieved by extracting and evaluating customer feedback, an invaluable source of real-time information. Swift actions on constructive feedback allows organisations to align their offerings as per the customer’s expectations, boosting customer satisfaction and business growth.

Remember, continuous improvement is not a one-time effort, but an ongoing activity that keeps organisations competitive in relentless markets. Organisations that align with the principles of ISO 9001 and implement it into their continuous improvement strategy can attain and maintain excellence in operations and services, setting a high industry standard.

Seeking integration of ISO 9001:2015 with other management systems is integral for businesses striving for operational excellence and efficiency. This undertaking can be significantly streamlined using comprehensive platforms like ISMS.online, designed to simplify this often-complex, resource-intensive process.

ISO 9001 belongs to the family of quality management systems developed to support organisations in fulfilling customer and stakeholder needs. Its focus is centred on multiple quality management principles, such as a customer-centric approach, top management involvement, process-oriented approach, and persistent improvement.

In terms of interaction with other management standards defining a sequential ‘Plan, Do, check, Act’ (PDCA) cycle, ISO 9001 collaborates seamlessly within our IMS or integrated management system. It synchronises effectively with Annex L standards like ISO 14001 for Environmental Management System, ISO 27001 for Information Security Management System, ISO 45001 for Occupational Health and Safety System, among others.

To integrate ISO 9001 effectively with the aforementioned systems, organisations need to identify, understand, align and document their processes, considering the requirements of ISO 9001 and those of the respective standards. Successful integration brings about a comprehensive approach to organisational management.

The benefits of such integration stretch beyond operational efficiency and compliance capabilities–they significantly influence customer satisfaction, enhance quality assurance, and bolster risk management.

For instance, imagine an automobile manufacturing firm with both ISO 9001 and ISO 14001 certifications. During production, the factory generates a significant amount of waste materials. The integration of ISO 9001 and ISO 14001 could ensure not only the quality assurance of the vehicles (ISO 9001) but also environmentally responsible disposal or recycling of waste materials (ISO 14001).

As such, challenges associated with the implementation of integrated management systems can feel daunting. Still, with solutions like ISMS.online, integrating various systems becomes an achievable objective. With the right tools and guidance, companies can fully harness the potential of integrated management systems, making a significant contribution to the organisation’s success.

Globally recognised, ISO 9001 is a quality management standard that underlines the crucial role well-drafted and comprehensive documentation play in fostering efficiency and building trust within enterprises. A thorough understanding of the key constituents, processes, and best practices to follow when creating ISO 9001 documentation can significantly aid in effectively implementing this standard.

To start, it’s crucial to understand the major constituents of ISO 9001 documentation which are procedures, instructions, and records. Each element carries its own unique importance, contributing to the smooth sailing and operation of an organisation’s quality management systems.

Procedures map out the actions and steps required for carrying out specific tasks or responsibilities. Meanwhile, Instructions offer a detailed guide of how specific tasks are to be performed. Lastly, Records, the documented proof of procedure execution, are essential for demonstrating compliance with the ISO 9001 standard.

To better explain, imagine a manufacturing firm implementing ISO 9001. The company would have procedures that demonstrate the steps for carrying out a quality acceptance test, instructions that detail the operations on the production line, and records confirming that these procedures and instructions have been duly followed.

Processes and procedures form an integral part of ISO 9001 documentation. They can range in complexity depending on the tasks they govern. For instance, a procedure for a quality acceptance test would entail steps like testing the product components, evaluating their efficiency, documenting the findings and making improvements as required. This systematic – and documented – method guarantees consistent quality of the output, thus reducing uncertainties and building trust with customers.

Book a tailored hands-on session

based on your needs and goals

Book your demo

A significant part of managing ISO 9001 documentation lies in mastering document control and record-keeping. A solid document control structure includes accurate document classification, timely reviews, consistent updates and secure storage of documents. This can be achieved in a company by setting periodic reviews for all procedures and instructions, making use of a digital system for secure document storage, and maintaining strict control over versioning of documents.

Similarly, meticulous record-keeping is crucial for demonstrating adherence to the ISO 9001 standard. A useful tip would be to organise records into categories related to specific processes or tasks. This not only makes it easier to retrieve these records during audits but also serves as a robust proof of consistent compliance.

The magic of ISO 9001 documentation lies in its ability to optimise processes, reduce errors, improve accountability, and foster a culture of continuous quality enhancement. By understanding and implementing these core components, managing procedural documentation, and adeptly handling document control and record-keeping, organisations can truly harness the power of ISO 9001 documentation..

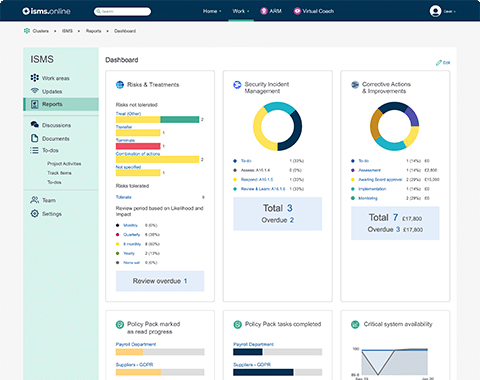

ISMS.online takes the lead in providing strategic solutions for a successful integration of ISO 9001 standards into organisations’ existing systems.

Three central services form the crux of their offerings:

These services, focusing on decoding ISO 9001 standards complexity, ensuring seamless integration, and efficient documentation processes, can be instrumental for organisations aiming to attain, and uphold ISO 9001 compliance. The support and resources offered by ISMS.online position organisations strategically on their path towards being ISO 9001 compliant.

ISMS.online is a

one-stop solution that radically speeded up our implementation.

Take 30 minutes to see how ISMS.online saves you hours (and hours!)

Book a meeting