ISO 27001 A.7.8 Equipment Siting and Protection Checklist

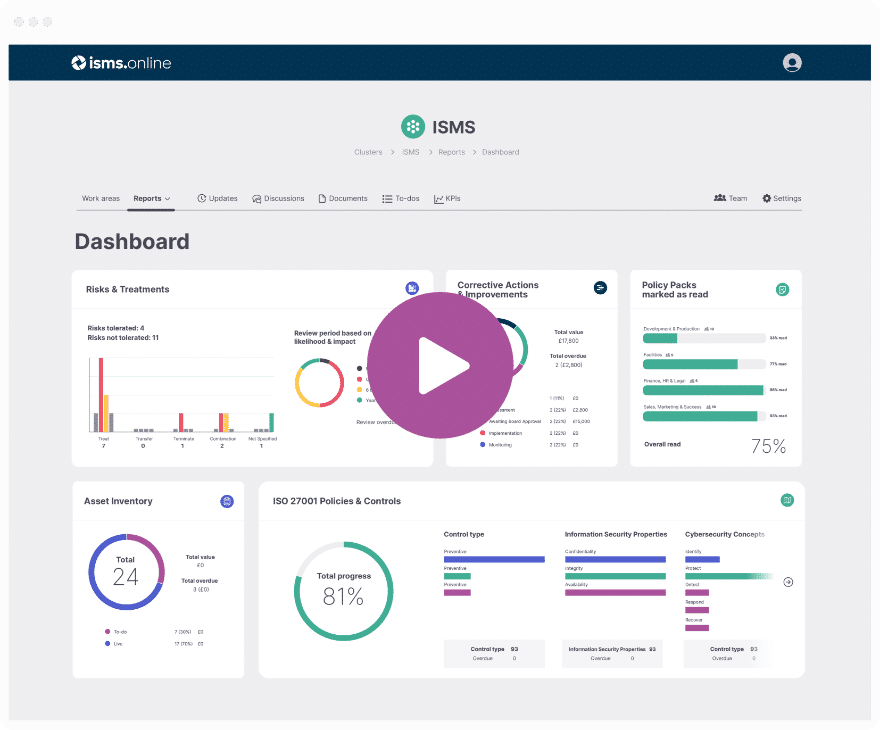

This control is crucial for maintaining the integrity, availability, and confidentiality of information processed, stored, or transmitted by the equipment. Implementing this control involves strategic planning, risk assessment, physical security, environmental protection, and continuous monitoring. The control applies to all critical equipment within the organisation, including servers, networking devices, storage systems, and other IT infrastructure components. We've done the hard work for you, giving you an 81% Headstart from the moment you log on.Scope of Annex A.7.8

Get an 81% headstart

All you have to do is fill in the blanks.

Why Should You Comply With Annex A.7.8? Key Aspects and Common Challenges

1. Equipment Siting:

Location Selection: Choose locations that minimise environmental risks such as fire, flood, or extreme temperatures. Consider building structure, climate control, and proximity to other equipment that may pose a risk.

- Identifying optimal locations that balance accessibility and security.

- Ensuring chosen locations do not interfere with other operations.

- Adapting to constraints of existing building structures and layouts.

- Solutions:

- Conduct comprehensive site assessments and risk analyses to identify suitable locations.

- Use simulation tools to model environmental risks and their impact.

- Collaborate with architects and facility planners to optimise layouts.

- Clause 6.1: Identify risks and opportunities related to the siting of equipment.

Challenges:

Access Control: Implement physical access controls to ensure only authorised personnel can access sensitive equipment. This may involve secure rooms, cages, or other physical barriers.

- Balancing security with operational efficiency and ease of access for authorised personnel.

- Implementing advanced access control systems within budget constraints.

- Regularly updating and maintaining access control lists.

- Solutions:

- Utilise biometric and multi-factor authentication systems to enhance access control.

- Regularly review and update access control policies and lists.

- Implement audit trails to track access attempts and ensure accountability.

- Clause 7.2: Ensure competence and awareness of personnel managing access controls.

- Clause 9.2: Conduct internal audits to verify the effectiveness of access controls.

Challenges:

Proximity Considerations: Ensure equipment is placed in locations that facilitate maintenance and operations without causing interference or hazards to personnel or other equipment.

- Coordinating with various departments to ensure maintenance schedules and operational needs are met.

- Avoiding potential hazards caused by equipment proximity.

- Solutions:

- Establish clear protocols for equipment placement and maintenance access.

- Conduct regular coordination meetings with relevant departments.

- Use zoning and signage to demarcate safe areas around critical equipment.

- Clause 8.1: Plan and control operations to ensure proper siting of equipment.

Challenges:

2. Environmental Protection:

Climate Control: Ensure appropriate environmental controls, such as air conditioning and ventilation systems, to maintain optimal operating conditions. Monitoring systems should be in place to detect and respond to deviations.

- Integrating climate control systems with existing infrastructure.

- Ensuring continuous monitoring and rapid response to climate deviations.

- Managing costs associated with installing and maintaining climate control systems.

- Solutions:

- Implement automated climate control systems with real-time monitoring.

- Use predictive maintenance tools to anticipate and prevent system failures.

- Allocate budget for periodic upgrades and maintenance of climate control systems.

- Clause 7.4: Ensure effective communication of environmental control procedures.

Challenges:

Power Supply: Equip critical systems with uninterruptible power supplies (UPS) and backup generators to protect against power outages and fluctuations. Regular maintenance and testing of these systems are essential.

- Ensuring the reliability of UPS and backup generators.

- Regularly testing and maintaining backup power systems to prevent failures.

- Budgeting for and procuring reliable power supply systems.

- Solutions:

- Develop a comprehensive maintenance schedule for power supply systems.

- Conduct regular drills to test the effectiveness of UPS and backup generators.

- Establish contracts with reliable suppliers for equipment and maintenance services.

- Clause 8.3: Ensure readiness for power supply and continuity measures.

Challenges:

Fire Protection: Install fire detection and suppression systems to protect equipment from fire hazards. This includes smoke detectors, fire alarms, and appropriate fire suppression agents that are safe for electronic equipment.

- Choosing fire suppression systems that do not harm electronic equipment.

- Integrating fire protection systems with existing security measures.

- Training staff on emergency procedures related to fire protection systems.

- Solutions:

- Use inert gas fire suppression systems that are safe for electronics.

- Integrate fire detection with building management systems for coordinated response.

- Conduct regular fire drills and training sessions for all relevant staff.

- Clause 7.3: Enhance awareness and training related to fire safety.

Challenges:

3. Security Measures:

Physical Security: Implement physical security measures such as locks, security cameras, and alarms to protect equipment from theft, vandalism, or unauthorised access.

- Ensuring comprehensive coverage of security systems without blind spots.

- Balancing the cost of advanced security technologies with budget constraints.

- Keeping security systems up-to-date with the latest technology.

- Solutions:

- Conduct security audits to identify and eliminate blind spots.

- Implement a layered security approach combining physical and electronic measures.

- Allocate budget for periodic upgrades and maintenance of security systems.

- Clause 6.2: Define security objectives and plan to achieve them.

Challenges:

Monitoring: Continuously monitor physical and environmental conditions to detect and respond to potential threats promptly. This includes surveillance systems and environmental sensors.

- Ensuring continuous and reliable monitoring without interruptions.

- Analysing and responding to monitoring data in real-time.

- Integrating various monitoring systems into a cohesive security framework.

- Solutions:

- Use integrated security management platforms for real-time monitoring and alerts.

- Implement machine learning algorithms to analyse monitoring data and detect anomalies.

- Conduct regular reviews and updates of monitoring protocols.

- Clause 9.1: Monitor, measure, analyse, and evaluate security performance.

Challenges:

Documentation and Review: Maintain detailed documentation of the equipment siting and protection measures. Regularly review and update these measures to ensure they remain effective and aligned with current risks and best practices.

- Keeping documentation current with frequent updates and changes.

- Ensuring all stakeholders have access to the latest documentation.

- Regularly reviewing and improving documentation processes to reflect best practices.

- Solutions:

- Implement a document management system with version control.

- Schedule regular reviews and updates of documentation with stakeholder input.

- Use collaboration tools to ensure all relevant parties have access to the latest information.

- Clause 7.5: Maintain documented information as required by the ISMS.

Challenges:

Annex A.7.8 Implementation Tips

Conduct a Thorough Risk Assessment: Identify potential environmental and physical threats to equipment.

- Gathering accurate and comprehensive data for risk assessment.

- Engaging all relevant stakeholders in the assessment process.

- Continuously updating risk assessments to reflect new threats.

- Solutions:

- Use risk assessment tools and methodologies to gather comprehensive data.

- Hold workshops and meetings with stakeholders to ensure thorough assessment.

- Establish a process for continuous risk assessment and updating.

- Clause 6.1: Identify and assess risks and opportunities.

Challenges:

Engage with Stakeholders: Include facilities management and IT teams to ensure comprehensive protection strategies.

- Coordinating between multiple departments with different priorities and schedules.

- Ensuring all stakeholders are committed to and understand their roles in the protection strategy.

- Solutions:

- Establish a cross-functional team for equipment siting and protection.

- Hold regular coordination meetings and update sessions.

- Develop clear communication channels and documentation to ensure alignment.

- Clause 5.1: Leadership and commitment from all relevant stakeholders.

Challenges:

Regularly Test and Review Protective Measures: Ensure their effectiveness and compliance with organisational policies and regulatory requirements.

- Scheduling regular tests without disrupting normal operations.

- Ensuring tests are comprehensive and simulate realistic scenarios.

- Keeping up with evolving regulatory requirements and best practices.

- Solutions:

- Develop a testing schedule that minimises operational disruptions.

- Use simulation tools to create realistic test scenarios.

- Stay informed about regulatory changes and update testing protocols accordingly.

- Clause 9.3: Conduct management reviews to ensure the effectiveness of the ISMS.

Challenges:

Compliance doesn't have to be complicated.

We've done the hard work for you, giving you an 81% Headstart from the moment you log on.

All you have to do is fill in the blanks.

ISMS.online Features for Demonstrating Compliance with A.7.8

- Asset Management:

- Asset Registry: Track the location and status of all critical equipment with a comprehensive asset registry. This ensures that equipment placement is documented and monitored.

- Labelling System: Implement a labelling system to identify and classify equipment, ensuring that it is easily identifiable and its location is well-documented.

- Risk Management:

- Dynamic Risk Map: Utilise the dynamic risk map to identify and assess environmental and physical risks associated with equipment siting. This helps in proactive risk mitigation and planning.

- Risk Monitoring: Continuously monitor identified risks and their mitigation status to ensure that all protective measures remain effective.

- Policy Management:

- Policy Templates: Use policy templates to create detailed policies and procedures for equipment siting and protection, ensuring that all measures are standardised and communicated.

- Document Access: Maintain and control access to documentation related to equipment siting and protection policies, ensuring that relevant stakeholders have access to the latest information.

- Incident Management:

- Incident Tracker: Track and manage any incidents related to equipment siting and protection, ensuring timely response and documentation of lessons learned.

- Workflow: Implement workflows for incident response to ensure that all incidents are handled consistently and effectively.

- Audit Management:

- Audit Templates: Use audit templates to regularly review and assess compliance with equipment siting and protection policies. This ensures ongoing adherence to standards and identification of improvement areas.

- Corrective Actions: Document and track corrective actions resulting from audits to ensure continuous improvement in equipment protection measures.

Detailed Annex A.7.8 Compliance Checklist

1. Equipment Siting:

- Location selection considers environmental threats (fire, flood, extreme temperatures).

- Physical access controls are implemented (secure rooms, cages, barriers).

- Equipment placement facilitates maintenance and avoids hazards.

- Proximity to other equipment is managed to prevent interference.

- Locations are periodically reviewed for continued suitability.

2. Environmental Protection:

- Climate control systems are in place (air conditioning, ventilation).

- Monitoring systems detect and respond to climate deviations.

- UPS and backup generators protect against power outages.

- Regular maintenance and testing of power supply systems.

- Fire detection and suppression systems are installed and safe for electronics.

- Environmental sensors are deployed to monitor conditions continuously.

3. Security Measures:

- Physical security measures (locks, cameras, alarms) are implemented.

- Continuous monitoring of physical and environmental conditions.

- Documentation of equipment siting and protection measures is maintained.

- Regular reviews and updates of protection measures.

- Security systems are integrated with other safety and monitoring systems.

- Regular training for staff on security and emergency procedures.

4. Implementation Tips:

- Conduct a thorough risk assessment for environmental and physical threats.

- Engage stakeholders (facilities management, IT teams) in protection strategies.

- Regularly test and review protective measures for effectiveness and compliance.

- Implement a continuous improvement process for equipment siting and protection.

- Ensure alignment with organisational policies and regulatory requirements.

- Establish a feedback mechanism for continuous improvement.

By following this comprehensive compliance checklist and leveraging ISMS.online features, organisations can effectively demonstrate adherence to A.7.8 Equipment Siting and Protection, ensuring the safety and security of their critical equipment.

Manage all your compliance in one place

ISMS.online supports over 100 standards

and regulations, giving you a single

platform for all your compliance needs.

Every Annex A Control Checklist Table

ISO 27001 Annex A.5 Control Checklist Table

ISO 27001 Annex A.6 Control Checklist Table

| ISO 27001 Control Number | ISO 27001 Control Checklist |

|---|---|

| Annex A.6.1 | Screening Checklist |

| Annex A.6.2 | Terms and Conditions of Employment Checklist |

| Annex A.6.3 | Information Security Awareness, Education and Training Checklist |

| Annex A.6.4 | Disciplinary Process Checklist |

| Annex A.6.5 | Responsibilities After Termination or Change of Employment Checklist |

| Annex A.6.6 | Confidentiality or Non-Disclosure Agreements Checklist |

| Annex A.6.7 | Remote Working Checklist |

| Annex A.6.8 | Information Security Event Reporting Checklist |

ISO 27001 Annex A.7 Control Checklist Table

| ISO 27001 Control Number | ISO 27001 Control Checklist |

|---|---|

| Annex A.7.1 | Physical Security Perimeters Checklist |

| Annex A.7.2 | Physical Entry Checklist |

| Annex A.7.3 | Securing Offices, Rooms, and Facilities Checklist |

| Annex A.7.4 | Physical Security Monitoring Checklist |

| Annex A.7.5 | Protecting Against Physical and Environmental Threats Checklist |

| Annex A.7.6 | Working in Secure Areas Checklist |

| Annex A.7.7 | Clear Desk and Clear Screen Checklist |

| Annex A.7.8 | Equipment Siting and Protection Checklist |

| Annex A.7.9 | Security of Assets Off-Premises Checklist |

| Annex A.7.10 | Storage Media Checklist |

| Annex A.7.11 | Supporting Utilities Checklist |

| Annex A.7.12 | Cabling Security Checklist |

| Annex A.7.13 | Equipment Maintenance Checklist |

| Annex A.7.14 | Secure Disposal or Re-Use of Equipment Checklist |

ISO 27001 Annex A.8 Control Checklist Table

How ISMS.online Help With A.7.8

Are you ready to ensure the highest level of protection for your critical equipment? With ISMS.online, you can streamline your compliance efforts, safeguard your assets, and mitigate risks effectively.

Our comprehensive platform offers robust tools for asset management, risk monitoring, policy management, and more, all designed to help you achieve and maintain compliance with ISO/IEC 27001:2022.

Don’t leave your equipment security to chance. Experience the power of ISMS.online firsthand and see how our solutions can transform your approach to equipment siting and protection.

Contact us today to book a demo and take the first step towards a more secure future.