What is ISO 14001 Clause 10 – Improvement

Primary Focus of ISO 14001 Clause 10

ISO 14001 Clause 10 emphasises continual improvement within an Environmental Management System (EMS). It aims to enhance environmental performance by systematically addressing nonconformities and implementing corrective actions.

Contribution to Continual Improvement in EMS

Clause 10 fosters a culture of continual improvement by requiring organisations to identify, document, and rectify nonconformities. This proactive approach ensures that environmental performance is consistently enhanced, aligning with the broader goals of ISO 14001 [Clause 10.1].

Key Components of Clause 10

- Nonconformity and Corrective Action: Identifying and addressing nonconformities to prevent recurrence.

- Continual Improvement: Regularly evaluating and improving the EMS to achieve better environmental outcomes.

- Documentation and Record-Keeping: Maintaining records of nonconformities, corrective actions, and improvements to ensure transparency and accountability [Clause 10.2].

Alignment with Overall Goals of ISO 14001

Clause 10 aligns with ISO 14001’s overall goals by promoting a systematic approach to environmental management. It supports the standard’s emphasis on compliance, risk management, and performance enhancement, ensuring organisations meet their environmental objectives [Clause 4.1].

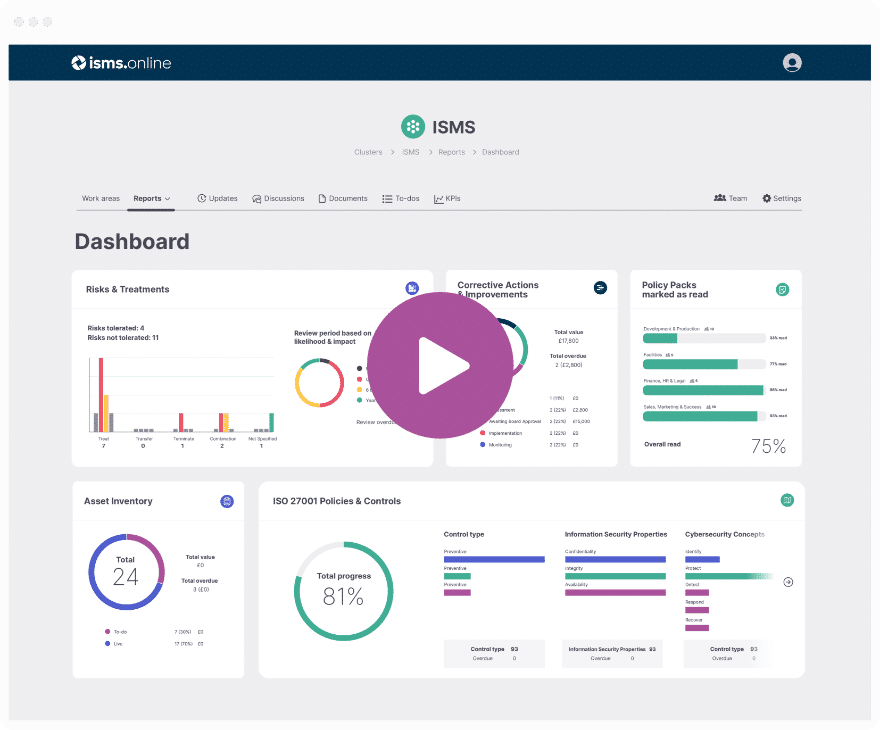

Introducing ISMS.online

ISMS.online streamlines the implementation of ISO 14001 Clause 10 by offering tools for nonconformity management, corrective actions, and continual improvement. Our platform provides real-time data tracking, automated compliance updates, and comprehensive documentation management, ensuring your organisation meets ISO 14001 requirements efficiently.

Book a demoUnderstanding Nonconformity Management

What Constitutes a Nonconformity Under ISO 14001?

A nonconformity in the context of ISO 14001 is any deviation from the requirements of the Environmental Management System (EMS) or the standard itself. This can include failures to meet environmental objectives, breaches of compliance obligations, or lapses in operational controls [Clause 10.2].

Identifying and Documenting Nonconformities

Nonconformities should be identified through regular monitoring, audits, and employee feedback. It’s essential to document each nonconformity comprehensively, including details of the incident, its impact, and any immediate corrective actions taken. This documentation ensures transparency and provides a basis for further analysis and action [Clause 9.2].

Steps for Managing Nonconformities

- Detection: Identify nonconformities through audits, inspections, and employee reports.

- Documentation: Record the nonconformity, its context, and any immediate actions.

- Root Cause Analysis: Investigate to determine the underlying causes.

- Corrective Action: Develop and implement actions to address the root cause and prevent recurrence.

- Verification: Ensure the effectiveness of corrective actions through follow-up audits and monitoring.

- Review: Regularly review nonconformities and corrective actions to identify trends and areas for improvement [Clause 10.2].

Contribution to Improvement

Effective nonconformity management is crucial for continual improvement. By systematically addressing and rectifying nonconformities, organisations can prevent recurrence, enhance compliance, and improve overall environmental performance. This proactive approach fosters a culture of accountability and continuous enhancement, aligning with the broader goals of ISO 14001 [Clause 10.1].

ISMS.online supports this process by providing tools for real-time tracking, automated documentation, and comprehensive analysis, ensuring your organisation can efficiently manage nonconformities and drive continual improvement.

Get an 81% headstart

We’ve done the hard work for you, giving you an 81% Headstart from the moment you log on. All you have to do is fill in the blanks.

Conducting Root Cause Analysis

Purpose of Root Cause Analysis in Clause 10

Root cause analysis (RCA) is essential in ISO 14001 Clause 10 as it identifies the underlying reasons behind nonconformities. This process ensures that corrective actions address the actual causes rather than just symptoms, preventing recurrence and fostering continual improvement within the Environmental Management System (EMS) [Clause 10.2].

Methodologies for Root Cause Analysis

Several methodologies can be employed for RCA, including:

- 5 Whys: Asking “why” repeatedly until the root cause is identified.

- Fishbone Diagram (Ishikawa): Visualising potential causes across categories like materials, methods, and manpower.

- Failure Mode and Effects Analysis (FMEA): Systematically evaluating potential failure points and their impacts.

- Pareto Analysis: Prioritising causes based on their frequency or impact, often visualised as a Pareto chart.

These methodologies help in systematically dissecting nonconformities to uncover underlying issues.

Preventing Recurrence of Nonconformities

RCA prevents recurrence by ensuring that corrective actions target the root causes. By addressing these fundamental issues, organisations can eliminate the conditions that led to the nonconformity, thereby reducing the likelihood of similar problems arising in the future. This proactive approach aligns with ISO 14001’s emphasis on continual improvement and risk management [Clause 6.1].

Best Practices for Conducting Root Cause Analysis

To conduct effective RCA, consider the following best practices:

- Thorough Documentation: Record all findings and steps taken during the analysis to ensure transparency and accountability.

- Cross-Functional Teams: Involve personnel from different departments to gain diverse perspectives and insights.

- Data-Driven Approach: Use data and evidence to support findings and avoid assumptions.

- Regular Training: Ensure staff are trained in RCA methodologies to maintain consistency and effectiveness.

- Follow-Up: Verify the effectiveness of corrective actions through follow-up audits and continuous monitoring.

By adhering to these practices, organisations can enhance their RCA processes, leading to more effective corrective actions and sustained environmental performance improvements.

Implementing Corrective Actions

What Are Corrective Actions, and Why Are They Important?

Corrective actions are measures taken to eliminate the causes of nonconformities within an Environmental Management System (EMS). They prevent recurrence, ensuring similar issues do not arise in the future. This proactive approach enhances compliance, reduces environmental risks, and supports continual improvement (Clause 10.2).

How Should Corrective Actions Be Planned and Executed?

Corrective actions should be meticulously planned and executed through a structured process:

- Identify the Nonconformity: Detect and document the nonconformity, including its context and impact.

- Root Cause Analysis: Conduct a thorough analysis to determine the underlying causes.

- Develop Action Plan: Create a detailed plan outlining the steps to address the root causes, including responsibilities and timelines.

- Implement Actions: Execute the corrective actions as per the plan.

- Verify Effectiveness: Monitor and evaluate the effectiveness of the actions taken to ensure the nonconformity is resolved and does not recur.

- Document and Review: Maintain comprehensive records of the entire process and review regularly to identify trends and areas for further improvement (Clause 10.2).

What Criteria Determine the Effectiveness of Corrective Actions?

The effectiveness of corrective actions is determined by several criteria:

- Elimination of Root Causes: The actions should address and eliminate the root causes of the nonconformity.

- Prevention of Recurrence: There should be no recurrence of the same or similar nonconformities.

- Improved Performance: There should be measurable improvements in environmental performance and compliance.

- Stakeholder Satisfaction: The actions should meet the expectations of relevant stakeholders, including regulatory bodies and internal parties (Clause 9.1).

How Can Organisations Ensure Corrective Actions Lead to Continual Improvement?

Organisations can ensure corrective actions lead to continual improvement by:

- Integrating Actions into the EMS: Ensure corrective actions are part of the broader EMS processes and align with organisational goals.

- Regular Monitoring and Review: Continuously monitor the effectiveness of corrective actions and review them periodically to identify further improvement opportunities.

- Training and Awareness: Educate and train staff on the importance of corrective actions and their role in achieving continual improvement.

- Using Digital Tools: Use platforms like ISMS.online for real-time tracking, automated documentation, and comprehensive analysis, enhancing the efficiency and effectiveness of corrective actions (Clause 10.1).

By following these strategies, organisations can foster a culture of continual improvement, ensuring long-term sustainability and compliance.

Compliance doesn't have to be complicated.

We’ve done the hard work for you, giving you an 81% Headstart from the moment you log on. All you have to do is fill in the blanks.

Monitoring and Measuring Performance

Relevant Performance Metrics for Clause 10

Clause 10 of ISO 14001 emphasises continual improvement, making performance metrics essential. Key metrics include:

- Nonconformity Rates: Frequency and types of nonconformities detected.

- Corrective Action Effectiveness: Success rate of implemented corrective actions.

- Environmental Impact: Measures like emissions, waste generation, and resource consumption.

- Compliance Levels: Adherence to legal and voluntary environmental obligations.

- Stakeholder Satisfaction: Feedback from interested parties on environmental performance.

Monitoring and Measuring Performance

Performance should be monitored and measured systematically:

- Define Metrics: Establish clear, relevant performance indicators.

- Data Collection: Use audits, inspections, and real-time monitoring tools.

- Analysis: Evaluate data against set benchmarks and objectives.

- Reporting: Document findings and communicate them to stakeholders.

Tools and Techniques for Performance Measurement

Several tools and techniques enhance performance measurement:

- Digital Platforms: ISMS.online offers real-time data tracking, automated compliance updates, and performance dashboards.

- Audits: Regular internal and external audits to assess compliance and performance.

- Environmental Monitoring Systems: Tools for tracking emissions, waste, and resource use.

- Root Cause Analysis: Techniques like 5 Whys and Fishbone Diagrams to identify underlying issues.

Supporting Continual Improvement

Performance monitoring supports continual improvement by:

- Identifying Trends: Recognising patterns in nonconformities and corrective actions.

- Informing Decisions: Providing data-driven insights for strategic planning.

- Enhancing Accountability: Ensuring transparency and responsibility in environmental management.

- Driving Innovation: Highlighting areas for technological and process improvements.

By integrating these practices, organisations can foster a culture of continual improvement, aligning with ISO 14001’s objectives (Clause 10.1).

Ensuring Continual Improvement

Strategies for Continual Improvement

To ensure continual improvement, organisations can employ several strategies:

- Regular Audits and Reviews: Conducting frequent internal and external audits helps identify areas for improvement and ensures compliance with ISO 14001 standards (Clause 9.2).

- Performance Metrics: Establishing and monitoring key performance indicators (KPIs) relevant to environmental objectives enables organisations to track progress and identify trends (Clause 9.1).

- Feedback Mechanisms: Implementing robust feedback systems from stakeholders, including employees and customers, can provide insights into potential improvements (Clause 4.2).

Fostering a Culture of Continual Improvement

Creating a culture of continual improvement involves:

- Employee Engagement: Encouraging employee participation in environmental initiatives and providing training on ISO 14001 requirements fosters a sense of ownership and accountability (Clause 7.2).

- Recognition and Rewards: Acknowledging and rewarding contributions to environmental performance improvements can motivate staff and promote a proactive mindset.

- Transparency: Maintaining open communication about environmental goals, progress, and challenges builds trust and encourages collective effort (Clause 7.4).

Leadership’s Role in Continual Improvement

Leadership is crucial for driving continual improvement:

- Commitment and Vision: Top management must demonstrate a commitment to environmental goals and articulate a clear vision for continual improvement (Clause 5.1).

- Resource Allocation: Ensuring adequate resources—financial, technological, and human—supports the implementation of improvement initiatives (Clause 7.1).

- Setting Objectives: Leaders should establish SMART (Specific, Measurable, Achievable, Relevant, Time-bound) objectives aligned with the organisation’s environmental policy (Clause 6.2).

Integrating Continual Improvement into Daily Operations

To embed continual improvement into daily operations:

- Standard Operating Procedures (SOPs): Integrating improvement processes into SOPs ensures consistency and accountability (Clause 8.1).

- Real-Time Monitoring: Utilising digital tools like ISMS.online for real-time tracking and automated compliance updates enhances operational efficiency.

- Regular Training: Ongoing training programmes keep staff updated on best practices and new regulatory requirements, fostering a culture of continuous learning (Clause 7.3).

By implementing these strategies, fostering a supportive culture, and leveraging leadership, organisations can achieve sustained environmental performance improvements.

Manage all your compliance in one place

ISMS.online supports over 100 standards and regulations, giving you a single platform for all your compliance needs.

Documentation and Record-Keeping

Required Documentation for Clause 10 Compliance

For ISO 14001 Clause 10 compliance, organisations must maintain documentation that captures nonconformities, corrective actions, and continual improvement efforts. This includes records of identified nonconformities, root cause analyses, corrective action plans, and verification of the effectiveness of these actions (Clause 10.2).

Maintaining Records of Nonconformities and Corrective Actions

Records of nonconformities and corrective actions should be detailed and systematically organised. Each record must include the nature of the nonconformity, the root cause analysis, the corrective actions taken, and the results of follow-up evaluations. Utilising digital tools like ISMS.online can streamline this process by providing automated documentation and real-time tracking, ensuring records are comprehensive and up-to-date.

Best Practices for Documentation and Record-Keeping

- Consistency: Ensure all records follow a standardised format to facilitate easy retrieval and analysis.

- Accuracy: Document all details accurately, including dates, personnel involved, and specific actions taken.

- Timeliness: Update records promptly to reflect the most current information.

- Security: Protect records from unauthorised access and ensure they are stored in a secure, backed-up system.

- Accessibility: Make records easily accessible to relevant stakeholders for review and audits.

Supporting Transparency and Accountability

Effective documentation supports transparency and accountability by providing a clear trail of actions taken to address nonconformities and improve environmental performance. It allows for thorough audits and reviews, ensuring that all steps are traceable and verifiable. This transparency fosters trust among stakeholders and demonstrates the organisation’s commitment to continual improvement and compliance with ISO 14001 standards (Clause 9.2).

By integrating these practices, organisations can enhance their environmental management systems, ensuring they meet ISO 14001 requirements efficiently and effectively.

Further Reading

Aligning with Other ISO Standards

Integration with ISO 9001 (Quality Management)

ISO 14001 Clause 10 aligns seamlessly with ISO 9001, emphasising continual improvement and corrective actions. Both standards advocate for systematic identification, documentation, and resolution of nonconformities. This alignment ensures that quality and environmental objectives are met, fostering a culture of excellence and compliance across the organisation (Clause 10.2).

Synergies with ISO 45001 (Occupational Health and Safety)

ISO 14001 and ISO 45001 share a common framework for managing risks and improving performance. Clause 10’s focus on continual improvement and corrective actions complements ISO 45001’s emphasis on hazard identification and risk mitigation. Integrating these standards enhances overall organisational resilience, ensuring a safe and sustainable working environment (Clause 6.1).

Alignment with ISO 27001 (Information Security)

Clause 10 of ISO 14001 aligns with ISO 27001 by promoting a proactive approach to managing nonconformities and implementing corrective actions. Both standards emphasise the importance of identifying root causes and preventing recurrence, ensuring robust environmental and information security management systems. This integration supports comprehensive risk management and compliance (Clause 9.2).

Benefits of Integrating Clause 10 with Other ISO Standards

Integrating ISO 14001 Clause 10 with other ISO standards offers several benefits:

- Streamlined Processes: Harmonising procedures for nonconformity management and corrective actions reduces redundancy and enhances efficiency.

- Improved Compliance: A unified approach to compliance ensures adherence to multiple standards, reducing the risk of noncompliance.

- Enhanced Performance: Synergies between standards foster a culture of continual improvement, driving better environmental, quality, and safety outcomes.

- Resource Optimization: Shared resources and integrated management systems reduce costs and improve resource allocation.

ISMS.online facilitates this integration by providing tools for real-time tracking, automated documentation, and comprehensive analysis, ensuring your organisation meets multiple ISO standards efficiently.

Utilising Digital Tools for Improvement

Digital Tools for Managing Nonconformities and Corrective Actions

Digital tools streamline the management of nonconformities and corrective actions by automating detection, documentation, and resolution processes. Platforms like ISMS.online offer real-time tracking, automated alerts, and comprehensive dashboards, ensuring that nonconformities are promptly identified and addressed. These tools facilitate root cause analysis and corrective action planning, enhancing the efficiency and effectiveness of the EMS (Clause 10.2).

Enhancing Performance Monitoring and Measurement

Digital tools significantly enhance performance monitoring and measurement by providing real-time data collection and analysis. ISMS.online integrates environmental monitoring systems to track key performance indicators (KPIs) such as emissions, waste generation, and resource consumption. Automated reporting features allow for continuous performance evaluation, ensuring compliance with environmental objectives and facilitating continual improvement (Clause 9.1).

Advantages of Digital Tools for Documentation and Record-Keeping

Using digital tools for documentation and record-keeping offers several advantages, including improved accuracy, accessibility, and security. ISMS.online provides centralised document management, ensuring that records of nonconformities, corrective actions, and performance metrics are consistently updated and easily retrievable. This enhances transparency and accountability, supporting thorough audits and reviews (Clause 7.5).

Supporting the Overall Goals of Clause 10

Digital tools support the overall goals of Clause 10 by fostering a culture of continual improvement and proactive management. ISMS.online’s features, such as automated compliance updates and integrated performance dashboards, enable organisations to systematically address nonconformities and implement effective corrective actions. This alignment with ISO 14001’s requirements ensures that environmental performance is consistently enhanced, driving long-term sustainability and compliance (Clause 10.1).

By using digital tools, organisations can optimise their EMS, ensuring efficient management of nonconformities, robust performance monitoring, and comprehensive documentation, ultimately achieving the continual improvement mandated by ISO 14001 Clause 10.

Overcoming Common Challenges

Common Challenges in Implementing Clause 10

Implementing ISO 14001 Clause 10 can present several challenges, including identifying and managing nonconformities, ensuring effective corrective actions, and fostering a culture of continual improvement. Organisations may also struggle with maintaining comprehensive documentation and integrating Clause 10 with other ISO standards.

Addressing Resistance to Change

Resistance to change is a common obstacle. To overcome this, organisations should engage employees through transparent communication and training programmes. Highlighting the benefits of Clause 10, such as improved environmental performance and compliance, can foster buy-in. Leadership must demonstrate commitment and involve staff in decision-making processes to build trust and acceptance (Clause 5.1).

Mitigating Resource Constraints

Resource constraints can hinder the effective implementation of Clause 10. Organisations can mitigate this by prioritising actions based on risk and impact, ensuring efficient allocation of resources. Leveraging digital tools like ISMS.online can streamline processes, reduce manual workload, and provide real-time data tracking, thereby optimising resource use (Clause 7.1).

Ensuring Compliance with Evolving Regulations

Staying compliant with evolving regulations requires continuous monitoring and adaptation. Organisations should establish robust compliance tracking systems and regularly review regulatory updates. Utilising platforms like ISMS.online, which offer automated compliance updates and integrated performance dashboards, can help organisations stay ahead of regulatory changes and ensure ongoing compliance (Clause 9.1).

By addressing these challenges proactively, organisations can enhance their Environmental Management Systems, ensuring effective implementation of ISO 14001 Clause 10 and driving continual improvement.

Practical Examples and Case Studies

Successful Implementation of Clause 10

Organisations across various industries have implemented ISO 14001 Clause 10 effectively, showcasing its role in driving continual improvement. For instance, a manufacturing company achieved a 20% reduction in waste generation within a year by systematically addressing nonconformities and enhancing corrective action processes. Similarly, an energy company utilised digital tools to track and manage nonconformities, resulting in a 15% improvement in compliance with environmental regulations and a significant reduction in environmental incidents.

Lessons from Real-World Applications

Real-world applications of Clause 10 offer several key lessons. First, thorough documentation and root cause analysis are essential for effective nonconformity management. Second, involving cross-functional teams in the corrective action process ensures diverse perspectives and comprehensive solutions. Third, using digital tools like ISMS.online enhances efficiency by automating documentation, real-time tracking, and performance monitoring.

Guiding the Implementation Process

Practical examples provide valuable guidance for implementing Clause 10. Organisations should prioritise identifying and documenting nonconformities, conducting root cause analyses, and developing detailed corrective action plans. Utilising platforms like ISMS.online can streamline these processes, ensuring that corrective actions are effectively implemented and monitored for continual improvement.

Measurable Benefits of Effective Implementation

Effective implementation of Clause 10 yields measurable benefits, including improved environmental performance, reduced nonconformities, and enhanced compliance with regulations. Organisations also experience increased stakeholder satisfaction and a stronger culture of continual improvement. By systematically addressing nonconformities and implementing corrective actions, businesses can achieve long-term sustainability and compliance with ISO 14001 standards (Clause 10.2).

Book a Demo With ISMS.online

Assisting With ISO 14001 Clause 10 Compliance

ISMS.online simplifies ISO 14001 Clause 10 compliance by offering tools that streamline nonconformity management, corrective actions, and continual improvement. Our platform ensures that your organisation can systematically address and rectify nonconformities, enhancing overall environmental performance (Clause 10.2).

Supporting Nonconformity Management and Corrective Actions

ISMS.online provides robust features for nonconformity management, including real-time tracking, automated alerts, and comprehensive dashboards. These tools facilitate the identification, documentation, and resolution of nonconformities, ensuring that corrective actions are effectively planned and executed. By integrating root cause analysis methodologies, our platform helps prevent recurrence and supports continual improvement (Clause 10.2).

Enhancing Performance Monitoring and Continual Improvement

Our platform enhances performance monitoring through real-time data collection and analysis. ISMS.online integrates environmental monitoring systems to track key performance indicators (KPIs) such as emissions, waste generation, and resource consumption. Automated reporting features allow for continuous performance evaluation, ensuring compliance with environmental objectives and facilitating continual improvement (Clause 9.1).

Book a Demo With ISMS.online Today

Using ISMS.online for integrated management systems (IMS) offers several benefits:

- Streamlined Processes: Harmonising procedures for nonconformity management and corrective actions reduces redundancy and enhances efficiency.

- Improved Compliance: A unified approach to compliance ensures adherence to multiple standards, reducing the risk of noncompliance.

- Enhanced Performance: Synergies between standards foster a culture of continual improvement, driving better environmental, quality, and safety outcomes.

- Resource Optimization: Shared resources and integrated management systems reduce costs and improve resource allocation.

By using ISMS.online, your organisation can achieve sustained environmental performance improvements, ensuring long-term sustainability and compliance with ISO 14001 standards. Book a demo today to see how our platform can transform your environmental management system.

Book a demo

Interested in an ISMS.online platform tour?

Start your free 2-minute interactive demo now and experience the magic of ISMS.online in action!

Try it for freeWe’re a Leader in our Field

"ISMS.Online, Outstanding tool for Regulatory Compliance"

-Jim M.

"Makes external audits a breeze and links all aspects of your ISMS together seamlessly"

-Karen C.

"Innovative solution to managing ISO and other accreditations"

-Ben H.