ISO 14001 vs ISO 9001

Primary Differences Between ISO 14001 and ISO 9001

ISO 14001 focuses on Environmental Management Systems (EMS), aiming to enhance environmental performance, comply with regulations, and achieve sustainability goals. Conversely, ISO 9001 targets Quality Management Systems (QMS), emphasising customer satisfaction, product quality, and continual improvement.

Scope Differences

ISO 14001’s scope includes managing environmental aspects, impacts, and compliance obligations (Clause 4.3), while ISO 9001 covers quality objectives, customer requirements, and process effectiveness. ISO 14001 applies to environmental performance, whereas ISO 9001 is concerned with quality outcomes.

Main Objectives

ISO 14001 aims to minimise environmental impact, ensure legal compliance, and promote sustainability (Clause 5.2). ISO 9001 seeks to enhance customer satisfaction, improve product quality, and streamline processes (Clause 6.2).

Complementary Nature

ISO 14001 and ISO 9001 complement each other by integrating environmental and quality management, fostering a holistic approach to organisational performance. Implementing both standards can lead to improved efficiency, reduced waste, and enhanced stakeholder trust.

Introducing ISMS.online

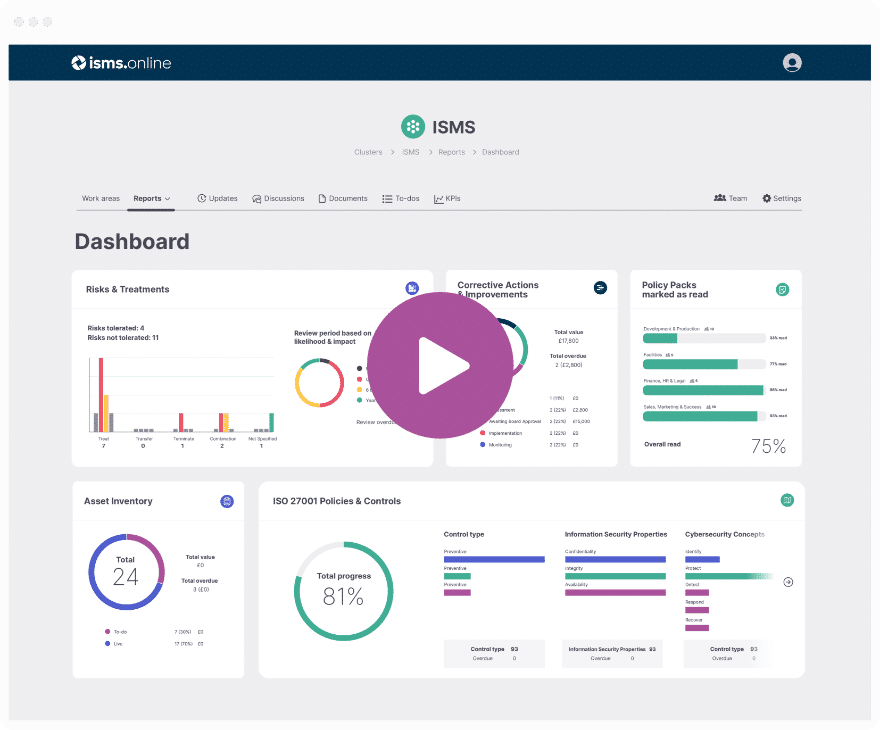

ISMS.online simplifies ISO 14001 and ISO 9001 compliance through features like risk management, document control, and performance monitoring. Our platform supports Integrated Management Systems (IMS), ensuring seamless alignment with both standards, enhancing overall organisational resilience and sustainability.

Book a demoScope and Applicability

Industries Implementing ISO 14001 and ISO 9001

ISO 14001 is widely adopted across industries with significant environmental impacts, such as manufacturing, construction, energy, and waste management. For example, a manufacturing plant might implement ISO 14001 to manage emissions and waste, ensuring compliance with environmental regulations. Conversely, ISO 9001 is prevalent in sectors prioritising quality and customer satisfaction, including healthcare, finance, and education. A hospital, for instance, might use ISO 9001 to enhance patient care quality and streamline administrative processes.

Application to Organisational Structures

ISO 14001 applies to organisations of all sizes, focusing on environmental aspects and impacts (Clause 4.3). It is particularly beneficial for companies with complex supply chains or those subject to stringent environmental regulations. For example, a multinational corporation might use ISO 14001 to ensure consistent environmental practices across its global operations. ISO 9001, on the other hand, is versatile, fitting various organisational structures by emphasising process efficiency and customer requirements. A small business might implement ISO 9001 to improve product quality and customer satisfaction, ensuring consistent service delivery.

Key Areas of Focus

ISO 14001 centres on environmental performance, legal compliance, and sustainability goals (Clause 6.1). Key areas include pollution prevention, resource efficiency, and waste management. For instance, a company might implement energy-saving measures and waste reduction strategies to meet ISO 14001 requirements. ISO 9001 focuses on quality objectives, customer satisfaction, and continual improvement (Clause 6.2), covering product quality, process optimization, and customer feedback. A software company might use ISO 9001 to refine its development processes, ensuring high-quality software releases and improved customer feedback mechanisms.

Impact of Scope on Implementation

The scope of ISO 14001 affects its implementation by necessitating a thorough assessment of environmental aspects and impacts, requiring organisations to develop robust environmental policies and procedures (Clause 5.2). For example, a company might conduct an environmental impact assessment to identify areas for improvement and develop policies to mitigate negative impacts. ISO 9001’s scope influences implementation through a focus on quality management principles, necessitating detailed documentation of processes and performance metrics. A manufacturing company might document its production processes and establish performance metrics to ensure consistent product quality.

ISMS.online supports the implementation of both standards by offering tools for risk management, document control, and performance monitoring. Our platform ensures that organisations can seamlessly integrate ISO 14001 and ISO 9001, enhancing overall compliance and operational efficiency. For instance, ISMS.online’s risk management tools help identify and mitigate risks, while document control features ensure that all necessary documentation is up-to-date and easily accessible.

Get an 81% headstart

We’ve done the hard work for you, giving you an 81% Headstart from the moment you log on. All you have to do is fill in the blanks.

Key Principles and Frameworks

Foundational Principles of ISO 14001 and ISO 9001

ISO 14001 is grounded in principles of environmental stewardship, legal compliance, and ongoing enhancement of environmental performance (Clause 5.2). This standard emphasises the need for organisations to minimise their environmental impact through systematic management of environmental aspects and impacts. For instance, a manufacturing company might implement ISO 14001 to manage emissions and waste, ensuring compliance with environmental regulations.

ISO 9001 focuses on quality management principles such as customer focus, leadership, engagement of people, process approach, and data-driven decision-making (Clause 5.1). This standard aims to enhance customer satisfaction by consistently providing products and services that meet customer and regulatory requirements. For example, a healthcare provider might use ISO 9001 to improve patient care quality and streamline administrative processes.

Supporting Continuous Improvement

Both ISO 14001 and ISO 9001 employ the Plan-Do-Check-Act (PDCA) cycle to foster continuous improvement. This iterative model ensures that organisations systematically plan actions, execute them, monitor outcomes, and make necessary adjustments to enhance performance (Clause 10.1). For example, a company might use the PDCA cycle to implement energy-saving measures, monitor their effectiveness, and adjust strategies based on performance data.

Core Elements of the PDCA Cycle

- Plan: Set objectives and processes to achieve desired outcomes in line with organisational policies. For instance, an organisation might plan to reduce its carbon footprint by setting specific targets for energy consumption.

- Do: Implement the planned processes. This could involve installing energy-efficient equipment or adopting new production techniques.

- Check: Monitor and measure processes against policies, objectives, and requirements, then report results. For example, the organisation might track energy usage and compare it to the set targets.

- Act: Take actions to continually improve process performance. Based on the monitoring results, the organisation might implement further improvements or corrective actions to achieve its energy reduction goals.

Integration with Other Management Systems

ISO 14001 and ISO 9001 can be integrated with other standards like ISO 45001 (Occupational Health and Safety) and ISO 27001 (Information Security) through the Annex SL framework. This common structure facilitates the creation of an Integrated Management System (IMS), boosting overall organisational efficiency and compliance. For example, a company might integrate ISO 14001, ISO 9001, and ISO 45001 to manage environmental, quality, and safety aspects within a unified framework.

ISMS.online supports this integration by offering tools for risk management, document control, and performance monitoring, enabling organisations to manage multiple standards within a unified platform. This holistic approach simplifies compliance and drives continuous improvement across all business areas. For instance, ISMS.online’s risk management tools help identify and mitigate risks, while document control features ensure that all necessary documentation is up-to-date and easily accessible.

Environmental Management System (EMS) vs Quality Management System (QMS)

Main Components of an EMS under ISO 14001

An Environmental Management System (EMS) under ISO 14001 comprises several key components:

- Environmental Policy: Establishes the organisation’s commitment to environmental protection, legal adherence, and ongoing enhancement.

- Planning: Identifies environmental aspects, compliance obligations, and risks and opportunities, setting objectives and planning actions.

- Support: Ensures resources, competence, awareness, communication, and documented information.

- Operation: Controls operational processes, manages lifecycle stages, and prepares for emergencies.

- Performance Evaluation: Monitors, measures, analyses, and evaluates environmental performance, including internal audits and management reviews.

- Improvement: Addresses nonconformities, implements corrective actions, and drives continual enhancement.

Main Components of a QMS under ISO 9001

A Quality Management System (QMS) under ISO 9001 includes:

- Quality Policy: Defines the organisation’s commitment to quality and customer satisfaction.

- Planning: Establishes quality objectives, addresses risks and opportunities, and plans changes.

- Support: Manages resources, competence, awareness, communication, and documented information.

- Operation: Controls production and service provision, including design and development.

- Performance Evaluation: Monitors, measures, analyses, and evaluates quality performance, including internal audits and management reviews.

- Improvement: Manages nonconformities, implements corrective actions, and drives continual enhancement.

Addressing Compliance and Performance Improvement

Both EMS and QMS address compliance through systematic processes for identifying and fulfilling legal and regulatory requirements. Performance improvement is driven by the PDCA cycle, ensuring continuous enhancement of environmental and quality outcomes.

Benefits of Implementing EMS and QMS Together

Implementing EMS and QMS together offers numerous benefits:

- Enhanced Efficiency: Streamlines processes, reducing waste and improving resource use.

- Integrated Compliance: Simplifies adherence to environmental and quality regulations.

- Improved Stakeholder Trust: Demonstrates commitment to sustainability and quality, enhancing reputation.

- Holistic Management: Facilitates a unified approach to managing environmental and quality aspects, supported by ISMS.online’s Integrated Management System (IMS) features, ensuring seamless alignment and continuous improvement.

Compliance doesn't have to be complicated.

We’ve done the hard work for you, giving you an 81% Headstart from the moment you log on. All you have to do is fill in the blanks.

Compliance and Regulatory Requirements

Compliance Obligations for ISO 14001 and ISO 9001

ISO 14001 requires organisations to identify and comply with environmental regulations, legal requirements, and other obligations related to their environmental aspects (Clause 6.1.3). This involves understanding the environmental impact of their activities and ensuring adherence to relevant laws. ISO 9001 mandates adherence to quality-related statutory and regulatory requirements, ensuring products and services meet customer and legal standards (Clause 8.2.2). This includes maintaining product quality and meeting customer expectations.

Meeting Regulatory Requirements

ISO 14001 helps organisations systematically manage environmental compliance through risk assessments, environmental objectives, and operational controls (Clause 8.1). For instance, a manufacturing company might implement waste management practices to comply with local environmental laws, such as reducing emissions and properly disposing of hazardous materials. ISO 9001 ensures quality compliance by establishing processes for monitoring, measuring, and evaluating product and service conformity (Clause 9.1.1). This might involve regular quality inspections and audits to meet industry standards and customer requirements.

Consequences of Non-Compliance

Non-compliance with ISO 14001 can result in legal penalties, environmental damage, and reputational harm. For example, failing to manage hazardous waste properly could lead to fines and environmental degradation. ISO 9001 non-compliance may lead to product recalls, customer dissatisfaction, and loss of market share. A company producing defective products might face customer complaints and financial losses, impacting its reputation and profitability.

Ensuring Ongoing Compliance

Organisations ensure ongoing adherence to ISO 14001 and ISO 9001 by conducting regular internal audits, management reviews, and continuous improvement initiatives (Clause 9.2). For instance, an internal audit might identify areas of non-compliance, prompting corrective actions to address deficiencies. ISMS.online supports these efforts with tools for audit scheduling, compliance tracking, and performance monitoring, ensuring organisations maintain adherence to both standards and drive continual improvement. This holistic approach enhances overall operational efficiency and regulatory compliance.

Risk Management and Opportunities

Addressing Risk Management in ISO 14001 and ISO 9001

Both ISO 14001 and ISO 9001 emphasise risk management as a core component. ISO 14001 focuses on identifying and mitigating environmental risks to prevent adverse impacts (Clause 6.1.1). For example, a company might assess the risk of water pollution from its operations and implement measures to prevent contamination. ISO 9001 targets risks affecting product quality and customer satisfaction, ensuring consistent delivery of high-quality products and services (Clause 6.1). For instance, a manufacturer might evaluate the risk of production delays and develop strategies to mitigate them.

Methods for Identifying and Assessing Risks

Both standards employ systematic approaches to risk identification and assessment. ISO 14001 requires evaluating environmental aspects and impacts, considering factors like emissions, resource use, and waste generation (Clause 6.1.2). For example, a manufacturing company might assess the risk of chemical spills and implement controls to prevent contamination. ISO 9001 mandates identifying risks related to quality management processes, such as supplier reliability and production defects (Clause 6.1). A company might assess the risk of supplier delays and develop contingency plans to ensure timely delivery of materials.

Promoting Opportunities for Improvement

ISO 14001 and ISO 9001 encourage identifying opportunities for improvement alongside risk management. ISO 14001 promotes opportunities to enhance environmental performance, such as adopting renewable energy sources or improving waste management practices (Clause 6.1.4). For instance, a company might invest in solar panels to reduce its carbon footprint. ISO 9001 fosters opportunities to improve product quality and customer satisfaction, such as refining production processes or enhancing customer feedback mechanisms (Clause 6.1.4). A business might implement advanced quality control techniques to reduce defects and increase customer satisfaction.

Risk-Based Thinking Approaches

Risk-based thinking is integral to both ISO 14001 and ISO 9001. ISO 14001 encourages integrating risk management into the environmental management system, ensuring proactive identification and mitigation of environmental risks (Clause A.5.2). For example, a company might implement a monitoring system to detect potential environmental hazards early. ISO 9001 emphasises considering risks and opportunities throughout the quality management system, promoting a culture of continuous improvement and resilience (Clause A.5.2). A company might use customer feedback to identify areas for quality improvement and implement changes accordingly.

ISMS.online supports these risk-based approaches with tools for risk identification, assessment, and mitigation, helping organisations maintain compliance and drive continuous improvement. For instance, ISMS.online’s risk management features enable organisations to track and manage risks effectively, ensuring they can respond promptly to any issues that arise.

Manage all your compliance in one place

ISMS.online supports over 100 standards and regulations, giving you a single platform for all your compliance needs.

Documentation and Record Keeping

Documentation Requirements for ISO 14001 and ISO 9001

ISO 14001 mandates maintaining information to support the Environmental Management System (EMS) and demonstrate compliance (Clause 7.5). This includes environmental policies, objectives, risk assessments, and records of compliance obligations. ISO 9001 requires information to ensure the Quality Management System (QMS) is effectively implemented, covering quality policies, objectives, process documentation, and customer requirements (Clause 7.5).

Managing Documented Information

Organisations manage information by establishing controls for creation, updating, and protection. This involves defining responsibilities, ensuring accessibility, and maintaining integrity. For example, ISMS.online offers tools for document control, enabling organisations to manage and track changes efficiently, ensuring compliance with both standards.

Best Practices for Maintaining Records

Best practices include regular reviews, secure storage, and easy retrieval. Implementing version control to track changes and ensuring only the latest versions are in use is crucial. Training staff on document management procedures is essential. ISMS.online’s document control features support these practices by providing a centralised platform for managing all necessary documentation.

Supporting Compliance and Performance

Effective documentation supports compliance and performance by providing a clear framework for managing processes and demonstrating adherence to standards. Accurate records enable organisations to track progress, identify areas for improvement, and ensure transparency during audits. ISMS.online facilitates this by offering real-time data tracking and automated reporting, helping organisations maintain compliance and drive continuous improvement.

Further Reading

Performance Evaluation and Improvement

Measuring Performance in ISO 14001 and ISO 9001

Both standards measure performance through systematic monitoring, measurement, analysis, and evaluation processes. ISO 14001 focuses on environmental compliance, assessing adherence to policies, objectives, and legal requirements (Clause 9.1). ISO 9001 evaluates quality performance, ensuring products and services meet customer and regulatory standards (Clause 9.1.1).

Key Performance Indicators (KPIs)

Key Performance Indicators (KPIs) for ISO 14001 include metrics such as energy consumption, waste generation, and emission levels. For example, a company might track its carbon footprint to measure environmental impact. ISO 9001 KPIs focus on product quality, customer satisfaction, and process efficiency, such as defect rates and customer complaint resolution times. These KPIs help organisations monitor progress and identify areas for improvement.

Conducting Internal Audits

Organisations conduct internal audits to verify compliance and effectiveness. Internal audits involve planning, executing, and reporting on the audit findings. For ISO 14001, audits assess environmental management practices, ensuring adherence to environmental policies and regulatory requirements (Clause 9.2). ISO 9001 audits evaluate quality management processes, verifying that quality objectives and customer requirements are met (Clause 9.2.2). ISMS.online supports audit scheduling, documentation, and follow-up actions, streamlining the audit process.

Steps for Continual Improvement

Continual improvement follows the Plan-Do-Check-Act (PDCA) cycle. Organisations set improvement objectives, implement actions, monitor outcomes, and make necessary adjustments. For ISO 14001, this might involve enhancing waste management practices or reducing energy consumption (Clause 10.1). ISO 9001 focuses on improving product quality and customer satisfaction, such as refining production processes or enhancing customer feedback mechanisms (Clause 10.3). ISMS.online facilitates continual improvement by providing tools for performance tracking, risk management, and document control, ensuring organisations can effectively implement and sustain improvements.

Leadership and Commitment

Role of Top Management in ISO 14001 and ISO 9001

Top management is pivotal in both ISO 14001 and ISO 9001, steering strategic direction and aligning the Environmental Management System (EMS) and Quality Management System (QMS) with organisational goals. Their dedication is essential for establishing policies, setting objectives, and allocating resources (Clause 5.1). For instance, a manufacturing company might set a goal to reduce carbon emissions by 20% over five years, requiring top management to allocate resources for new technologies and processes.

Driving Success Through Leadership and Commitment

Effective leadership and commitment are fundamental to the success of ISO 14001 and ISO 9001. By fostering a culture of continuous improvement and accountability, top management ensures that environmental and quality objectives are met. For example, they might champion initiatives to reduce waste or enhance product quality, demonstrating their dedication to sustainability and customer satisfaction. A practical example could be a company implementing a zero-waste policy, with top management leading the charge by setting clear targets and monitoring progress.

Responsibilities of Management in Implementation

Management responsibilities in implementing ISO 14001 and ISO 9001 include defining roles and responsibilities, ensuring competence, and promoting awareness (Clause 5.3). They must also provide the necessary resources and support for effective system implementation. For example, management might invest in training programmes to enhance employee skills and knowledge, ensuring compliance with both standards. A real-world example could be a company conducting regular training sessions on quality control and environmental management practices to ensure all employees are competent and aware of their roles.

Fostering a Culture of Continuous Improvement

ISO 14001 and ISO 9001 foster a culture of continuous improvement through the Plan-Do-Check-Act (PDCA) cycle. Top management’s active involvement in reviewing performance, addressing nonconformities, and implementing corrective actions is essential (Clause 10.2). By regularly evaluating and improving processes, organisations can achieve better environmental and quality outcomes. For instance, a company might use the PDCA cycle to implement energy-saving measures, monitor their effectiveness, and adjust strategies based on performance data.

ISMS.online supports these efforts by offering tools for performance monitoring, risk management, and document control, enabling organisations to maintain compliance and drive continuous improvement. This holistic approach ensures that leadership and commitment translate into tangible results, enhancing overall organisational performance and sustainability. For example, ISMS.online’s risk management tools help identify and mitigate risks, while document control features ensure that all necessary documentation is up-to-date and easily accessible.

Integration with Other ISO Standards

Integrating ISO 14001 and ISO 9001 with ISO 45001 and ISO 27001

ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) can be seamlessly integrated with ISO 45001 (Occupational Health and Safety) and ISO 27001 (Information Security). This integration leverages the common structure provided by Annex SL, which standardises terminology, clauses, and requirements across ISO standards. For example, a manufacturing company might integrate these standards to manage environmental impacts, ensure product quality, maintain workplace safety, and protect information security, creating a comprehensive management system.

Benefits of an Integrated Management System (IMS)

An Integrated Management System (IMS) offers numerous benefits, including streamlined processes, reduced duplication of efforts, and enhanced overall efficiency. By combining multiple standards, organisations can address various compliance requirements through a unified approach, improving resource allocation and reducing administrative burdens. For instance, a company might use an IMS to align environmental, quality, safety, and security objectives, ensuring consistent performance across all areas.

Facilitating Integration with Annex SL

Annex SL provides a high-level structure that facilitates the integration of multiple ISO standards. It aligns clauses and terminology, making it easier for organisations to implement and manage an IMS. For example, Annex SL’s common framework ensures that risk management, performance evaluation, and continual improvement processes are consistent across standards, simplifying compliance and enhancing overall effectiveness.

Challenges and Solutions for Integrating ISO 14001 and ISO 9001

Integrating ISO 14001 and ISO 9001 can present challenges, such as aligning different objectives and managing increased complexity. Organisations may face difficulties in harmonising processes and ensuring staff competence across multiple standards. Solutions include using platforms like ISMS.online, which offers tools for risk management, document control, and performance monitoring, supporting seamless integration and continuous improvement. For example, ISMS.online’s centralised platform helps organisations manage compliance obligations and track performance metrics, ensuring successful integration of ISO 14001 and ISO 9001.

Implementation Challenges and Solutions

Common Challenges in Implementing ISO Standards

Organisations often face resource constraints, lack of expertise, and resistance to change when implementing Environmental Management Systems (EMS) and Quality Management Systems (QMS). For instance, small businesses may struggle with the financial and human resources needed to develop and maintain these systems. Additionally, the complexity of aligning existing processes with new standards can be daunting.

Overcoming Obstacles in the Implementation Process

To overcome these obstacles, organisations can engage external consultants, invest in employee training, and utilise digital tools like ISMS.online. Engaging stakeholders early and fostering a culture of continuous improvement can also mitigate resistance to change. For example, conducting workshops to educate employees on the benefits of ISO standards can enhance buy-in and support. Practical steps include setting up cross-functional teams to manage the transition and using pilot projects to test new processes before full-scale implementation.

Critical Success Factors for Implementing Both Standards

Key success factors include top management commitment, clear communication, and robust planning. Ensuring that leadership is actively involved in setting objectives and allocating resources is crucial (Clause 5.1). Additionally, integrating ISO standards into existing processes and aligning them with organisational goals can streamline implementation and enhance effectiveness. For instance, regular management reviews and performance evaluations can help track progress and identify areas for improvement.

How ISMS.online Supports Implementation

ISMS.online simplifies the implementation of ISO standards through features like risk management, document control, and performance monitoring. Our platform provides pre-configured templates, guided frameworks, and real-time data tracking, ensuring organisations can efficiently manage compliance and drive continuous improvement. For example, ISMS.online’s risk management tools help identify and mitigate risks, while document control features ensure that all necessary documentation is up-to-date and easily accessible. Additionally, our performance monitoring tools enable organisations to track key metrics, conduct internal audits, and implement corrective actions, ensuring ongoing compliance and improvement.

Book a Demo With ISMS.online

Streamlining ISO 14001 and ISO 9001 Compliance

ISMS.online simplifies adherence to ISO 14001 and ISO 9001 by offering a centralised platform for managing Environmental Management Systems (EMS) and Quality Management Systems (QMS). Our platform provides tools for risk management, document control, and performance monitoring, ensuring seamless alignment with both standards. For instance, our risk management features help identify and mitigate environmental and quality risks, ensuring compliance with relevant clauses (Clause 6.1.1).

Supporting Integrated Management Systems

ISMS.online supports Integrated Management Systems (IMS) by offering features that facilitate the integration of multiple ISO standards, including ISO 14001 and ISO 9001. Our document control capabilities ensure that all necessary documentation is up-to-date and easily accessible, while our performance monitoring tools track key metrics across various standards. This holistic approach simplifies compliance and enhances overall organisational efficiency.

Facilitating Continuous Improvement and Performance Tracking

Continuous improvement is at the core of both ISO 14001 and ISO 9001, and ISMS.online facilitates this through the Plan-Do-Check-Act (PDCA) cycle. Our platform provides tools for setting improvement objectives, implementing actions, monitoring outcomes, and making necessary adjustments. For example, our performance tracking features enable organisations to monitor energy consumption and product quality, ensuring ongoing enhancement (Clause 10.1).

Benefits of a Demo

Booking a demo with ISMS.online allows organisations to explore our platform's capabilities firsthand. During the demo, you'll see how our tools can streamline compliance, enhance performance, and support continuous improvement. Our experts will guide you through the features, demonstrating how ISMS.online can be tailored to meet your specific needs, ultimately driving efficiency and sustainability in your organisation.

Book a demo

Interested in an ISMS.online platform tour?

Start your free 2-minute interactive demo now and experience the magic of ISMS.online in action!

Try it for freeWe’re a Leader in our Field

"ISMS.Online, Outstanding tool for Regulatory Compliance"

-Jim M.

"Makes external audits a breeze and links all aspects of your ISMS together seamlessly"

-Karen C.

"Innovative solution to managing ISO and other accreditations"

-Ben H.